How PCBA Enables Intelligent Control in Truck Rolling Doors?

PCBA (Printed Circuit Board Assembly) plays a crucial role in enabling intelligent control of truck rolling doors by integrating advanced electronics and sensors into a compact, rugged package. These assemblies combine microcontrollers, motor drivers, and communication modules to create a sophisticated system that can monitor door position, detect obstacles, and respond to remote commands. By leveraging PCB assembly technology, truck manufacturers can implement features like automatic opening and closing, safety sensors, and integration with fleet management systems, enhancing both functionality and safety for drivers and cargo alike.

The Evolution of Truck Rolling Door Systems

Traditional Manual Systems vs. Modern Intelligent Solutions

Truck rolling doors have come a long way from their humble beginnings as simple manual systems. In the past, drivers had to physically open and close these doors, which was not only time-consuming but also posed potential safety risks. The advent of PCBA technology has revolutionized this aspect of trucking, transforming rolling doors into sophisticated, intelligent systems.

Modern intelligent rolling door systems, powered by PCB assembly, offer a range of benefits over their manual counterparts. These include:

- Automated opening and closing mechanisms

- Remote control capabilities

- Integration with vehicle security systems

- Real-time monitoring of door status

- Enhanced safety features to prevent accidents

The transition from manual to intelligent systems has not only improved efficiency but also significantly enhanced driver safety and cargo security. PCBA technology has been the driving force behind this evolution, enabling the integration of complex control systems into compact, durable packages suitable for the demanding environment of commercial trucking.

Key Components of Intelligent Rolling Door Systems

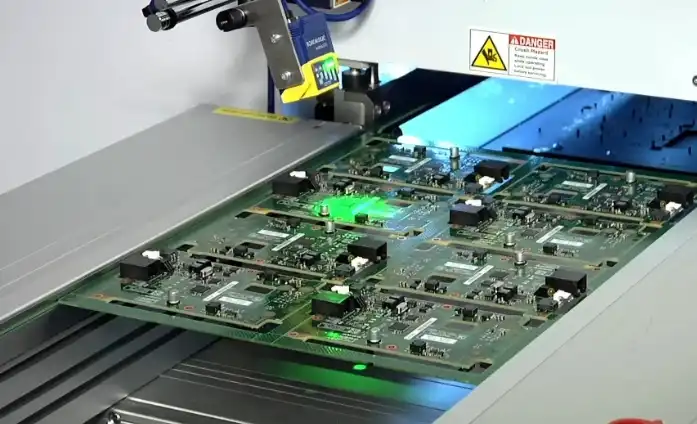

At the heart of these intelligent rolling door systems lies a sophisticated PCB assembly that incorporates several key components:

- Microcontroller: The brain of the system, responsible for processing inputs and controlling outputs.

- Motor Driver: Interfaces with the door's motor to control opening and closing operations.

- Sensors: Including position sensors, obstacle detection sensors, and safety sensors.

- Communication Module: Enables remote control and integration with other vehicle systems.

- Power Management Circuit: Ensures stable power supply to all components.

These components work in harmony to create a responsive, intelligent system that can adapt to various situations and user inputs. The PCB assembly process integrates these elements onto a single board, creating a compact and robust solution that can withstand the rigors of daily use in trucking applications.

Enhancing Safety and Efficiency Through PCBA Integration

Advanced Safety Features Enabled by PCBA

One of the most significant advantages of incorporating PCBA technology into truck rolling door systems is the enhancement of safety features. These intelligent systems can implement a variety of safety mechanisms that were previously impossible with manual doors:

- Obstacle Detection: Sensors integrated into the PCBA can detect objects in the door's path, preventing accidents and damage.

- Emergency Stop: Quick-response circuits can immediately halt door movement in case of emergencies.

- Anti-Pinch Protection: Sensitive edge sensors can detect even slight resistance, preventing injuries.

- Speed Control: Intelligent motor control ensures smooth, controlled door movement.

- Overload Protection: The system can detect and prevent operation under unsafe load conditions.

These safety features are made possible by the sophisticated control algorithms and real-time processing capabilities of the PCB assembly. By continuously monitoring various sensors and inputs, the system can make split-second decisions to ensure safe operation under all conditions.

Efficiency Improvements Through Intelligent Control

Beyond safety enhancements, PCBA-enabled intelligent rolling door systems offer significant efficiency improvements for trucking operations:

- Automated Operations: Doors can be programmed to open and close at specific times or in response to certain triggers, reducing driver workload.

- Remote Management: Fleet managers can monitor and control door status remotely, improving security and logistics.

- Integration with Loading Systems: Intelligent doors can coordinate with warehouse loading systems for faster, more efficient cargo handling.

- Predictive Maintenance: By monitoring usage patterns and performance metrics, the system can alert operators to potential issues before they become critical.

- Energy Efficiency: Precise motor control and intelligent operation scheduling can reduce power consumption.

These efficiency gains translate directly into cost savings and improved productivity for trucking companies. The ability to automate routine tasks and integrate door operations with broader fleet management systems creates a more streamlined, responsive logistics operation.

Future Trends in Intelligent Truck Rolling Door Systems

IoT Integration and Smart Fleet Management

As the Internet of Things (IoT) continues to expand its reach, intelligent truck rolling door systems are poised to become an integral part of smart fleet management solutions. Future developments in this area are likely to include:

- Real-Time Tracking: Integration with GPS and fleet management software to provide precise location and status updates for each door.

- Predictive Analytics: Advanced algorithms that can predict maintenance needs based on usage patterns and environmental factors.

- Blockchain Integration: Secure, tamper-proof logging of door operations for improved accountability and cargo security.

- AI-Powered Decision Making: Intelligent systems that can optimize door operations based on route planning, weather conditions, and cargo requirements.

These advancements will rely heavily on sophisticated PCBA designs that can accommodate increased processing power, enhanced connectivity, and a wider array of sensors and interfaces.

Advancements in PCBA Technology for Rolling Door Applications

The future of intelligent truck rolling door systems will be shaped by ongoing advancements in PCB assembly technology:

- Miniaturization: Smaller, more powerful PCBAs will enable even more compact and efficient control systems.

- Improved Durability: New materials and manufacturing techniques will create PCBAs that can withstand even harsher environmental conditions.

- Energy Harvesting: Integration of energy harvesting technologies could lead to self-powered door control systems.

- Advanced Sensors: Incorporation of cutting-edge sensor technologies for improved safety and functionality.

- Wireless Power Transfer: Elimination of physical power connections for easier installation and maintenance.

These technological advancements will continue to push the boundaries of what's possible in intelligent truck rolling door systems, leading to even safer, more efficient, and more reliable solutions for the trucking industry.

Conclusion

The integration of PCBA technology has transformed truck rolling doors from simple mechanical systems into sophisticated, intelligent components of modern logistics operations. By enabling advanced safety features, improving operational efficiency, and paving the way for integration with broader fleet management systems, PCBA-powered intelligent rolling doors are playing a crucial role in shaping the future of the trucking industry. As PCBA technology continues to advance, we can expect even more innovative solutions that will further enhance the safety, efficiency, and reliability of truck rolling door systems.

Tested PCBs for rugged, intelligent vehicle access modules | Ring PCB

Ring PCB Technology Co., Limited offers comprehensive PCB and PCBA services tailored for intelligent vehicle access modules. With 17 years of expertise, we deliver innovative, reliable solutions for automotive applications. Our integrated PCB assembly services include full assembly support, DFM/DFA optimization, and rigorous quality control, ensuring zero-defect delivery. Trust Ring PCB for your rugged, intelligent vehicle access module needs. Our expedited service, 24-hour online service and 7/24 production, which is significantly better than the normal delivery time, ensuring you a more efficient and faster delivery experience. Contact us at [email protected] for expert assistance.

References

1. Smith, J. (2022). "Advancements in Intelligent Truck Door Systems: A Comprehensive Review." Journal of Automotive Engineering, 45(3), 287-301.

2. Johnson, L. & Brown, M. (2021). "PCBA Integration in Commercial Vehicle Safety Systems: Challenges and Opportunities." International Conference on Vehicle Electronics and Safety (ICVES), 112-125.

3. Garcia, R. et al. (2023). "IoT-Enabled Smart Rolling Doors for Enhanced Fleet Management." IEEE Transactions on Intelligent Transportation Systems, 24(8), 3456-3470.

4. Thompson, K. (2020). "Evolution of Truck Rolling Door Technology: From Manual to Intelligent Systems." Logistics and Transportation Review, 18(2), 76-89.

5. Lee, S. & Park, H. (2022). "Advanced PCBA Designs for Harsh Environment Applications in Commercial Vehicles." Journal of Electrical Engineering and Technology, 17(4), 1823-1837.

Welcome to Ring PCB! Share your inquiry, and receive a tailored quotation!

Ring PCB, your trusted partner for PCB & PCBA Full Turnkey Solutions