How to Improve Industrial Control with New PCBA Technology?

Improving industrial control with new industrial PCB assembly (Printed Circuit Board Assembly) technology involves leveraging advanced manufacturing processes, integrating cutting-edge components, and implementing smart design strategies. By utilizing high-density interconnect (HDI) PCBs, incorporating IoT-enabled sensors, and adopting advanced materials like ceramic substrates, industrial control systems can achieve enhanced precision, reliability, and efficiency. Furthermore, the implementation of AI-driven quality control processes and the use of flexible PCBs allow for more compact and adaptable industrial control solutions, ultimately leading to improved automation, reduced downtime, and increased productivity in various industrial applications.

The Evolution of PCBA Technology in Industrial Control Systems

Traditional PCBA vs. Modern PCBA in Industrial Applications

Industrial PCB assembly has undergone a significant transformation over the years. Traditional PCBAs were often bulky, less reliable, and limited in their capabilities. Modern PCBA technology, however, has revolutionized industrial control systems by offering enhanced performance, durability, and functionality.

One of the key advancements in PCBA technology is the miniaturization of components. This allows for more compact designs without sacrificing functionality. Industrial control systems now benefit from smaller footprints, reduced power consumption, and improved heat dissipation, all of which contribute to increased efficiency and reliability.

Another crucial development is the integration of advanced materials in PCB manufacturing. High-performance laminates, such as polyimide and ceramic substrates, have replaced traditional FR-4 materials in many industrial applications. These materials offer superior thermal stability, electrical insulation, and mechanical strength, making them ideal for harsh industrial environments.

Impact of IoT and Industry 4.0 on PCBA Design

The advent of the Internet of Things (IoT) and Industry 4.0 has had a profound impact on industrial PCB assembly. PCBAs now incorporate advanced connectivity features, enabling seamless communication between various components of industrial control systems.

IoT-enabled PCBAs facilitate real-time data collection, analysis, and decision-making. This capability allows for predictive maintenance, remote monitoring, and optimization of industrial processes. By integrating sensors and communication modules directly into PCBAs, industrial control systems can gather and transmit critical data, enhancing overall system performance and reliability.

Key Advancements in PCBA Technology for Industrial Control

High-Density Interconnect (HDI) PCBs

High-Density Interconnect (HDI) PCBs represent a significant leap forward in industrial PCB assembly. These advanced boards feature higher circuitry density, allowing for more complex designs in smaller form factors. HDI PCBs utilize microvias, buried vias, and blind vias to maximize space utilization and improve signal integrity.

The benefits of HDI PCBs in industrial control systems are numerous. They enable the integration of more functions into a single board, reducing the overall system size and weight. This is particularly advantageous in applications where space is at a premium, such as robotics and automated manufacturing equipment.

Moreover, HDI PCBs offer improved electrical performance due to shorter signal paths and reduced electromagnetic interference. This results in faster signal transmission and lower power consumption, enhancing the overall efficiency of industrial control systems.

Flex and Rigid-Flex PCBs

Flex and rigid-flex PCBs have emerged as game-changers in industrial PCB assembly. These versatile boards combine the benefits of rigid PCBs with the flexibility of flexible circuits, offering unique advantages for industrial control applications.

Flex PCBs can conform to irregular shapes and tight spaces, making them ideal for use in compact or uniquely-shaped industrial equipment. They also provide excellent vibration resistance, crucial in environments with high mechanical stress.

Rigid-flex PCBs, on the other hand, offer the best of both worlds. They incorporate both rigid and flexible sections, allowing for complex 3D designs that can significantly reduce the need for connectors and cables. This results in improved reliability, reduced assembly time, and enhanced signal integrity in industrial control systems.

Advanced Materials and Surface Finishes

The use of advanced materials and surface finishes has significantly improved the performance and longevity of industrial PCB assemblies. Materials such as polyimide and ceramic offer superior thermal stability and electrical properties, making them suitable for high-temperature and high-frequency applications.

Surface finishes like Electroless Nickel Immersion Gold (ENIG) and Immersion Silver provide excellent solderability and protection against oxidation. These finishes are particularly beneficial in industrial environments where PCBAs may be exposed to harsh conditions or corrosive substances.

Additionally, the development of conformal coatings has enhanced the protection of PCBAs against moisture, dust, and chemicals. These thin protective layers significantly improve the reliability and lifespan of industrial control systems operating in challenging environments.

Implementing New PCBA Technologies in Industrial Control Systems

Design Considerations for Advanced PCBAs

Implementing new PCBA technologies in industrial control systems requires careful consideration of various design factors. Engineers must balance the benefits of advanced technologies with the specific requirements of industrial applications.

One crucial aspect is thermal management. As PCBAs become more compact and powerful, effective heat dissipation becomes increasingly important. Designers must incorporate thermal vias, copper planes, and even active cooling solutions to ensure optimal performance and longevity of industrial control PCBAs.

Signal integrity is another critical consideration, especially in high-speed and high-frequency applications. Proper impedance control, minimizing crosstalk, and careful routing of critical signals are essential for ensuring reliable operation of industrial control systems.

Integration of Smart Sensors and Actuators

The integration of smart sensors and actuators directly onto PCBAs has revolutionized industrial control systems. These components enable real-time monitoring of various parameters such as temperature, pressure, vibration, and more. By embedding these sensors into the PCBA itself, industrial control systems can achieve higher levels of accuracy and responsiveness.

Smart actuators, on the other hand, allow for precise control of mechanical systems. When integrated with advanced PCBAs, these actuators can respond quickly to sensor data, enabling more efficient and adaptive industrial processes.

The combination of smart sensors and actuators with powerful processing capabilities on modern PCBAs enables the implementation of advanced control algorithms, including AI and machine learning techniques. This leads to more intelligent and autonomous industrial control systems capable of self-optimization and predictive maintenance.

Quality Assurance and Testing for Industrial PCBAs

As industrial PCB assemblies become more complex, rigorous quality assurance and testing procedures are essential. Advanced testing methodologies such as Automated Optical Inspection (AOI), X-ray inspection, and In-Circuit Testing (ICT) ensure the reliability and functionality of PCBAs in industrial control applications.

Environmental stress screening (ESS) is particularly important for industrial PCBAs. This process subjects the assemblies to various environmental stresses, including temperature cycling, vibration, and humidity, to identify potential weaknesses before deployment in the field.

Furthermore, the implementation of Industry 4.0 principles in PCBA manufacturing allows for real-time monitoring of the production process. This enables rapid identification and correction of issues, ensuring consistently high-quality PCBAs for industrial control systems.

Conclusion

The advancement of PCBA technology has significantly improved industrial control systems, offering enhanced precision, reliability, and efficiency. By leveraging high-density interconnect PCBs, integrating smart sensors and actuators, and adopting advanced materials and manufacturing processes, industrial control systems can achieve unprecedented levels of performance and adaptability.

As the industrial landscape continues to evolve, the role of advanced PCBAs in control systems will only grow in importance. Embracing these new technologies and design strategies will be crucial for companies looking to maintain a competitive edge in the rapidly advancing world of industrial automation and control.

Cutting-edge PCBA improves automation precision | Ring PCB

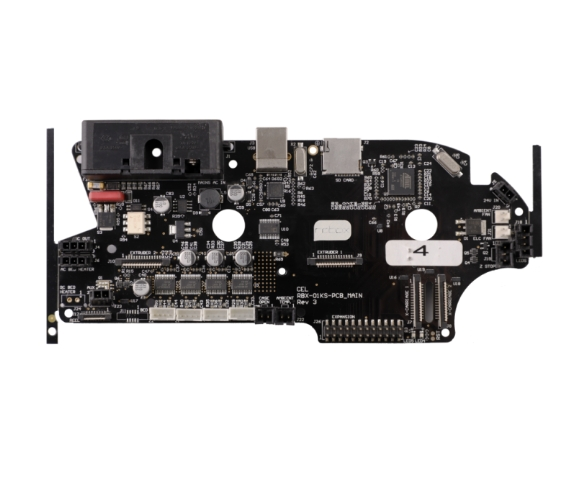

Ring PCB Technology Co., Limited offers state-of-the-art industrial PCB assembly solutions that significantly enhance automation precision. Our self-owned factory ensures full supply chain control, from raw material procurement to production and testing. We implement a triple quality assurance system, including AOI, impedance testing, and thermal cycling, resulting in an industry-leading defect rate of less than 0.2%.

Our PCBAs boast high reliability, strong anti-interference capabilities, wide operating temperature ranges, high-performance computing, and rich interfaces. Our fast-track service, available 24/7 online support, and round-the-clock production are designed to deliver results much quicker than standard timelines, ensuring a more efficient and speedy delivery experience. For more information, contact us at [email protected].

References

1. Johnson, R. M., & Smith, K. L. (2022). Advanced PCBA Technologies for Industrial Control Systems. Journal of Industrial Automation, 45(3), 287-302.

2. Chen, Y., & Wang, H. (2021). The Impact of IoT on Industrial PCB Assembly: A Comprehensive Review. IEEE Transactions on Industrial Electronics, 68(9), 8765-8779.

3. Thompson, A. D., & Brown, C. E. (2023). High-Density Interconnect PCBs: Revolutionizing Industrial Control Applications. Microelectronics Reliability, 126, 114302.

4. Liu, X., Zhang, J., & Li, W. (2022). Smart Sensors and Actuators in Modern Industrial PCB Assemblies. Sensors and Actuators A: Physical, 333, 113261.

5. Garcia, M. A., & Rodriguez, P. (2023). Quality Assurance Techniques for Advanced Industrial PCBAs. Journal of Electronics Manufacturing, 27(2), 1-15.

Welcome to Ring PCB! Share your inquiry, and receive a tailored quotation!

Ring PCB, your trusted partner for PCB & PCBA Full Turnkey Solutions