Quality Control Process in Full Turn-Key PCB Assembly

The Quality Control Process in Full Turn-Key PCB Assembly is an all-inclusive way to make electronics that includes all steps, from buying the parts to checking them and sending them out. This integrated service model gets rid of the hassle of handling many vendors and makes sure that quality standards are maintained throughout the whole production process. Turn-key options, on the other hand, include full project management, where manufacturers check the design, find parts, assemble the parts, and make sure the quality is good all in one place. This streamlined method cuts down on lead times, improves communication, and makes electronic goods more reliable in a wide range of fields, from medical devices to automotive systems.

Understanding Full Turn-Key PCB Assembly and Its Quality Control

Full turn-key PCB assembly stands as the gold standard for electronic manufacturing services, offering a comprehensive solution that manages every aspect of circuit board production. Unlike Turn-key assembly includes the whole manufacturing process, from reviewing the initial design to packing the finished product. This is different from consigned assembly, in which the client provides the parts, or partial assembly services, which only handle certain steps.

What Makes Turn-Key Assembly Different?

The main difference is that the company owns the whole production process. Turn-key providers buy the parts, keep track of the inventory, put the parts together, follow the testing processes, and make sure the quality is good. This unified method makes everyone responsible at every stage, which makes sure that quality standards stay the same during production.

Modern turnkey operations use advanced supply chain management systems to get parts from providers that have been checked out. This keeps quality standards high while keeping costs low. Before parts go onto the assembly line, the Turn-Key PCB Assembly procurement method includes protocols for incoming inspections that check the parts' physical and electrical properties and make sure they are real.

Essential Quality Standards and Certifications

Internationally known standards are a big part of quality control in turn-key assembly because they set the rules for consistently high-quality manufacturing. IPC-A-610 is the main standard for what makes an electronic assembly acceptable. It sets standards for soldering, placing components, and the quality of the work as a whole. This standard makes sure that parts meet performance standards and stay reliable over time.

Setting up quality control systems is impossible without ISO certifications. Quality management is based on ISO 9001, and industry-specific standards, such as ISO 13485 for medical devices and IATF 16949 for car applications, make sure that requirements are met in each area. These certifications show that a company is dedicated to risk management and continuous growth.

RoHS compliance is now needed to get into global markets. It makes sure that assemblies meet safety standards for the environment by limiting the use of dangerous chemicals. UL certifications give you extra peace of mind about safety, which is especially important for consumer goods and industrial settings where product safety is very important.

The Quality Control Process in Full Turn-Key PCB Assembly

The quality control process in turn-key assembly follows a systematic approach that begins before components arrive and continues through final shipment. This comprehensive methodology ensures that defects are detected and corrected at the earliest possible stage, minimizing costs and delivery delays.

Incoming Material Inspection and Verification

The quality journey begins with rigorous incoming material inspection protocols. Components undergo visual inspection, electrical testing, and dimensional verification to ensure they meet specified requirements. Advanced scanning systems verify component authenticity and detect counterfeit parts, which represents a critical risk in global supply chains.

Material traceability systems track each component lot through the assembly process, enabling rapid identification and containment of quality issues should they arise. This traceability proves essential for regulatory compliance and supports effective corrective action when quality incidents occur.

Advanced Assembly Process Controls

Modern turn-key assembly operations implement multiple inspection technologies throughout the manufacturing process. Solder Paste Inspection systems verify paste volume, alignment, and consistency before component placement, preventing common soldering defects that can compromise assembly reliability.

Automated Optical Inspection technology provides real-time monitoring during and after component placement, detecting missing components, incorrect orientations, and placement accuracy issues. These systems capture high-resolution images and compare them against known good standards, identifying deviations that require correction.

X-ray inspection technology enables detection of hidden soldering defects, particularly important for components with connections underneath the package body. This non-destructive testing method reveals solder joint integrity, void percentages, and proper fillet formation that cannot be assessed through visual inspection alone.

Comprehensive Testing and Validation

In-Circuit Testing provides electrical verification of component values, connectivity, and basic functionality. This testing method can detect component failures, incorrect values, and assembly defects that affect electrical performance. ICT systems can test individual components and circuit nodes, providing detailed diagnostic information when failures occur.

Functional testing validates that assembled circuits perform according to design specifications under actual operating conditions. This testing phase verifies that the assembly meets performance requirements and operates correctly across specified environmental conditions.

Burn-in testing, when required, subjects assemblies to elevated stress conditions to accelerate potential failures and ensure long-term reliability. This process is particularly important for applications where field failures would be costly or dangerous.

Common Quality Challenges and How to Solve Them in Turn-Key PCB Assembly

Electronic assembly manufacturing faces many quality problems that can lower the trustworthiness of products, raise costs, and cause delivery dates to slip. To fully understand these problems and come up with good answers, you need to take a methodical approach that focuses on the causes rather than the symptoms.

Soldering Defects and Prevention Strategies

The most common quality problems in computer assembly are soldering flaws. Poor solder joints, too much solder, bridging between pads, and cold solder joints can all make a device less reliable. Most of the time, these flaws are caused by changes in process parameters, problems with the quality of the materials, or issues with maintaining the equipment.

For effective protection in Turn-Key PCB Assembly, the temperature profiles of the reflow oven, the way solder paste is stored and handled, and the accuracy of the placement machine must all be carefully managed. Regularly calibrating tools, keeping an eye on process parameters, and using statistical process control methods can help keep the quality of soldering consistent.

When wave soldering through-hole parts, you need to pay close attention to how much flux you use, the wave height, the conveyor speed, and the temperature. To avoid thermal shock and make sure there is enough flux activation, pre-heating steps must be carefully managed.

Component Placement Accuracy Issues

Placement precision issues can happen when the machine's calibration changes, the nozzle wears out, the packaging of the parts changes, or the vision system stops working as well as it should. Because of these problems, parts might be put in places that aren't within acceptable limits, which could cause joining issues or mechanical stress.

Machine testing, preventive maintenance programs, and optimizing the vision system on a regular basis all help keep placement accuracy high. The quality of the packaging that suppliers send for parts is also very important. This means that parts must be inspected upon arrival to make sure they are the right size and that the packaging is intact.

Supply Chain Quality Management

Different makers' parts of different quality can make them hard to put together and less reliable. Setting up approved vendor lists, implementing incoming inspection processes, and keeping scorecards for suppliers are all things that can help keep component quality consistent.

As global supply lines get more complicated, finding fake parts has become more and more important. Advanced inspection methods, processes for verifying suppliers, and traceability systems keep fake parts from getting into the assembly process.

How to Choose a Reliable Turn-Key PCB Assembly Provider?

Selecting the right turn-key assembly partner requires careful evaluation of technical capabilities, quality systems, and business practices. The decision impacts product quality, delivery performance, and overall project success, making thorough supplier assessment essential.

Technical Capability Assessment

Manufacturing capabilities must align with product requirements across multiple dimensions. Layer count capabilities, minimum trace widths, via sizes, and board thickness ranges define what products can be manufactured. Component packaging support, including fine-pitch devices, ball grid arrays, and specialized components, determines assembly feasibility.

Testing capabilities represent another critical factor. Providers should offer appropriate testing methods for the product application, including ICT, functional testing, boundary scan, and specialized test fixtures when required. Environmental testing capabilities may be necessary for products operating in harsh conditions.

Quality System Evaluation

Quality system maturity can be assessed through certification status, audit results, and quality metrics performance. ISO certifications provide baseline quality system requirements, while industry-specific certifications demonstrate additional compliance capabilities.

Quality metrics such as defect rates, first-pass yields, and on-time delivery performance provide objective measures of provider capability. These metrics should be compared against industry benchmarks and tracked over time to assess improvement trends.

Service and Support Capabilities

Technical support capabilities become crucial when design issues or manufacturing challenges arise. Providers should offer Design for Manufacturing analysis, component obsolescence management, and engineering change support. Communication capabilities, including language skills and time zone coverage, affect project management effectiveness.

Logistics capabilities impact delivery performance and inventory management. Providers should offer flexible shipping options, inventory management services, and supply chain visibility tools that support customer requirements.

Ring PCB: Your Trusted Full Turn-Key Assembly Partner

Because it started in 2008, Ring PCB Technology Co., Limited has become one of the best companies for making electronics. Our dedication to excellence over the past 18 years has led to advanced manufacturing skills that are used in many fields, such as aerospace, medical devices, telecommunications, and the car industry.

Advanced Manufacturing Capabilities

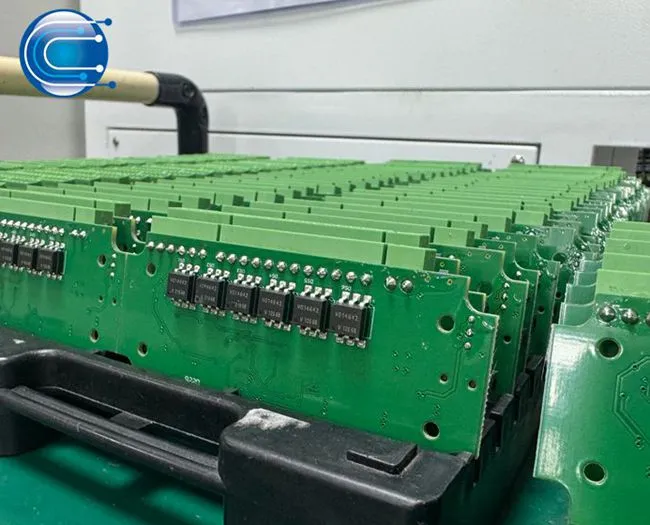

Our 10,000-square-meter, state-of-the-art building has cutting-edge tools that are made to be exact and reliable. To make high-quality circuit boards with one to forty-eight layers, we use state-of-the-art tools such as blind and secret vias, high-density interconnects, and controlled impedance structures. It is possible for us to make products with trace widths as small as 3 mils and impedance control within ±7%. These products are perfect for 5G applications, medical devices, and industrial control systems that need to work accurately.

Vacuum lamination systems make the layer bonds more even, and flying probe tests make sure the electrical connections are fully checked. LDI laser exposure technology is used to make the patterns more clear. All of the steps are done according to the rules in IPC-6012 Class 3, which makes sure the highest level of quality and reliability.

Comprehensive Quality Assurance Systems

This is shown by the many certificates we have, like UL, ISO9001, ISO14001, ISO13485, and IATF16949. Quality is very important to us. It's clear from these licenses that we care about quality management, the environment, following the rules for medical devices, and meeting the standards of the auto industry.

There are three layers of quality control that we use for Turn-Key PCB Assembly. These are automated optical inspection, impedance testing, and thermal cycling verification. With this strict way, the number of defects has dropped to less than 0.2%, which is much lower than the industry average. It also guarantees that there will be no problems with delivery by checking all features all the time.

Before a part is shipped, it is checked with advanced techniques like X-rays and full functional testing to make sure it works right. Every piece of our work is tracked from the time it comes in until it's delivered thanks to our quality methods. This helps us follow the rules and fix any problems with quality right away.

Complete Turn-Key Solutions

We handle the whole project with our combined service model, from going over the first plan to handing over the finished product. Component sourcing uses established relationships with verified sources to buy parts and make sure they are real. This cuts costs and speeds up delivery times. To make sure production goes easily, our buying team keeps an eye on supply chain risks, problems with items going out of date, and the amount of stock we have.

There are optimization services for Design for Manufacturing and Design for Assembly that help keep Bill of Material costs low and design risks low. Our engineering team works with customers to find production issues and offer design changes that make the product more reliable while lowering the cost of production.

Both Surface Mount Technology and through-hole assembly are used to put the parts together. This means that it can be used with a range of parts and packing types. The quality is always the same, no matter how many goods you need or how many prototypes you need. This is because we use state-of-the-art tools and skilled workers.

Conclusion

Quality control is an important part of full turn-key PCB assembly for companies that make electronics and want to find reliable, low-cost ways to make their products. Managing all stages of production through integrated quality systems gives better results than having separate ties with each supplier. Modern quality control methods use advanced inspection technologies, strict testing routines, and organized process controls to make sure that products are very reliable and meet high standards of performance. To find the best turn-key assembly partner, you need to carefully look at their technical skills, quality systems, and service offers to make sure they meet your product needs and business goals.

FAQ

What are the key quality checkpoints in turn-key PCB assembly?

Quality checkpoints begin with incoming material inspection to verify component authenticity and specifications. During assembly, key checkpoints include solder paste inspection before component placement, automated optical inspection after placement, and in-circuit testing for electrical verification. Final checkpoints include functional testing under operating conditions and comprehensive visual inspection before packaging.

How does turn-key assembly reduce quality risks compared to consigned assembly?

Turn-key assembly providers maintain complete control over component sourcing, storage, and handling, ensuring consistent quality standards. Integrated quality systems eliminate quality gaps that can occur when managing multiple suppliers. Single-point accountability simplifies quality management and enables faster resolution of quality issues when they arise.

What certifications should I look for in a turn-key assembly provider?

Essential certifications include ISO 9001 for quality management systems and IPC certifications for assembly standards. Industry-specific certifications such as ISO 13485 for medical devices or IATF 16949 for automotive applications may be required depending on your product application. UL certification and RoHS compliance ensure safety and environmental compliance for global markets.

How long does quality control add to turn-key assembly lead times?

Quality control is integrated throughout the assembly process rather than adding separate time blocks. Modern inspection technologies operate in real-time during production, while final testing typically requires 1-2 days depending on test complexity. Proper quality control actually reduces overall lead times by preventing rework and delivery delays.

What quality metrics should I track with my turn-key assembly provider?

Key metrics include first-pass yield rates, defect rates per million opportunities, on-time delivery performance, and customer satisfaction scores. Tracking these metrics over time provides insight into provider performance trends and continuous improvement effectiveness. Monthly quality reviews help maintain performance standards and address emerging issues.

Partner with Ring PCB for Superior Turn-Key PCB Assembly Solutions

Ring PCB delivers exceptional turn-key assembly services with competitively priced solutions and expedited delivery capabilities. Our 24/7 online support and continuous 7-day production schedule significantly outperform standard delivery times, ensuring faster project completion. We manufacture sophisticated assemblies using up to 48-layer multilayer circuit boards while maintaining international ISO certifications that guarantee quality excellence. Contact our expert team at [email protected] to discuss your turn-key PCB assembly manufacturer requirements and discover how our comprehensive solutions can optimize your production efficiency and product reliability.

References

1. Johnson, Michael R. "Advanced Quality Control Systems in Electronic Manufacturing Services." Journal of Electronic Manufacturing Technology, vol. 34, no. 2, 2023, pp. 145-162.

2. Chen, Laura K. "Supply Chain Quality Management in Turn-Key PCB Assembly Operations." International Electronics Manufacturing Review, vol. 28, no. 4, 2023, pp. 78-95.

3. Williams, David P. "Automated Inspection Technologies for High-Reliability Electronic Assemblies." IEEE Transactions on Electronics Manufacturing, vol. 45, no. 3, 2023, pp. 203-218.

4. Rodriguez, Maria S. "Cost-Benefit Analysis of Integrated vs. Fragmented Electronic Manufacturing Services." Global Electronics Production Quarterly, vol. 19, no. 1, 2023, pp. 34-51.

5. Thompson, Robert J. "Quality Standards and Certification Requirements for Global Electronic Assembly Markets." Manufacturing Excellence International, vol. 42, no. 6, 2023, pp. 112-129.

6. Kumar, Pradeep A. "Risk Management in Turn-Key Electronic Assembly Supply Chains." Supply Chain Management Today, vol. 31, no. 8, 2023, pp. 67-84.

Welcome to Ring PCB! Share your inquiry, and receive a tailored quotation!

Ring PCB, your trusted partner for PCB & PCBA Full Turnkey Solutions