Rigid-flex PCB assembly is a new way of putting together circuit boards that combines the structural integrity of rigid boards with the flexibility of flexible circuits. This makes it possible to build new solutions for today's demanding electronic applications. This technology lets producers make anything from medical gadgets to aircraft systems with better space efficiency, higher dependability, and less complicated assembly. These hybrid solutions are becoming more and more important for modern businesses that need to get around design limitations while yet meeting high performance criteria in tough working circumstances.

Understanding Rigid-Flex PCB Assembly and Its Advantages

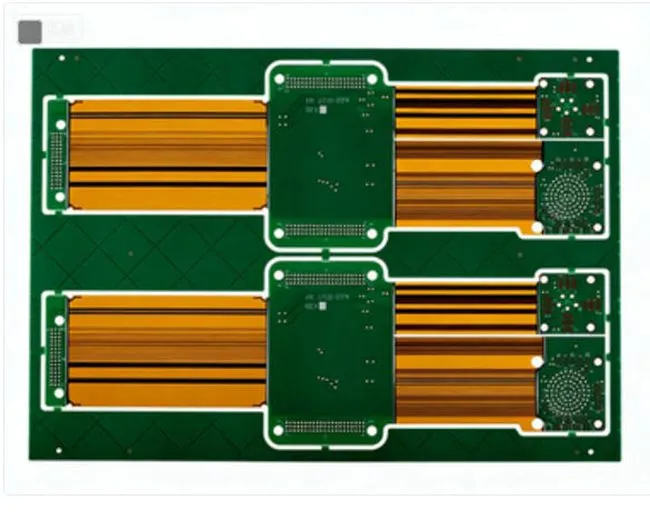

The unique way that rigid-flex technology is built is what makes it work. It combines hard circuit portions with flexible interconnects in a way that works well. This hybrid technique gets rid of the need for traditional connectors, which lowers the number of probable failure sites and allows for three-dimensional packing options that are not conceivable with standard PCB designs.

Core Benefits for Modern Electronics

When manufacturing experts use flexible-rigid PCB solutions in their product development plans, they see a number of clear benefits. These advantages directly deal with problems that purchasing managers and engineering teams in many different fields often have.

Space optimization is perhaps the most important benefit since it lets engineers compress circuits into small shapes while keeping their electrical integrity. Weight loss is especially important in situations where every gram counts, such portable medical gadgets or electronics for cars. Reduced connecting stress leads to better mechanical durability since flexible portions can handle movement and vibration that would normally break stiff connections.

Material Selection Impact

Choosing the right materials for a project may have a big effect on both performance and production costs. FR4 substrates are great for supporting stiff parts, whereas polyimide sheets are great for supporting flexible parts that need to be able to bend. To maintain continuous electrical continuity and mechanical stability throughout the product lifespan, careful engineering is needed at the contact between these materials.

The Rigid-Flex PCB Assembly Process Explained

Making rigid-flex assemblies requires complex procedures that need accuracy at every step. Because of how complicated it is, you need particular tools and knowledge to consistently get great results that match strict industry requirements, especially in rigid-flex PCB assembly.

Design Verification and Manufacturing Preparation

The procedure starts with a full design check utilizing modern CAD tools that can model both electrical and mechanical performance. Before production starts, engineers look at bend radius requirements, trace routing optimization, and material transition zones to find any problems with manufacturing. This first research cuts down on expensive revisions and makes sure that designs can be made.

Multi-Layer Lamination and Bonding

To make sure that stiff and flexible pieces stick together, lamination methods need very fine control of temperature and pressure. Specialized vacuum lamination equipment makes sure that the adhesion is uniform and that delamination doesn't happen in important regions. To keep the structure stable during temperature changes, the bonding procedure must take into consideration the varying thermal expansion coefficients of the materials.

Component Placement and Soldering Techniques

Assembly approaches change typical SMT procedures to fit the special needs of flexible-rigid substrates. When mounting components, automated placement equipment needs particular fittings to keep the dimensions stable. Careful tuning of reflow soldering profiles is necessary to protect flexible parts from harm while ensuring that reliable solder joints occur on stiff parts.

Expert Testing and Quality Validation

Before shipping, every assembly is put through a full set of tests to make sure it fulfills performance standards. Automated Optical Inspection systems check that the components are in the right position and that the solder joints are good. In-Circuit Testing checks that the electrical parts work, and flying probe testing let you check prototypes and low-volume manufacturing with more freedom.

Controlled bend testing is one of the mechanical testing techniques that checks the durability of flexible sections, while stress analysis is another that looks for possible failure causes. These validation steps make buying managers feel more sure that the products will work and lower the chances of them failing in the field.

Comparing Rigid-Flex PCB Assembly with Alternative Solutions

Knowing the pros and disadvantages of various PCB technologies helps people who buy things make smart choices based on the needs of the application and the budget.

Performance Comparison Analysis

Traditional rigid PCBs are great for situations where cost is important and the layout is simple. They are easy to make and have shorter lead times. But for designs with more than one part, they need outside connections, which makes assembly more complicated and adds more places where things may go wrong, especially in rigid-flex PCB assembly.

Pure flexible circuits are very adaptable, but they have problems with component density and managing heat. Costs of production are usually higher than those of rigid alternatives since they need particular materials and processing.

Rigid-flex solutions fill in these gaps by using the best parts of both technologies. Even while the initial prices may be higher than those of solely rigid options, the removal of connections and better dependability sometimes lead to cheaper overall system expenses.

Cost Factors and Timeline Considerations

Material prices make up a large part of overall expenditures, and polyimide substrates cost more than ordinary FR4. The need for specialized handling and complicated assembly procedures makes labor more intensive. But as you make more of anything, economies of scale become clear, which makes rigid-flex more appealing for industrial numbers.

For regular setups, lead times are usually between three and six weeks. However, there are also expedited options available for urgent needs. By planning procurement schedules around these times, you may minimize delays in product development cycles that cost a lot of money.

Practical Design Tips and Challenges in Rigid-Flex PCB Assembly

To successfully integrate rigid-flex, you need to know both the design principles and the manufacturing limits that determine how well things are made.

Design for Manufacturability Guidelines

Good DFM starts with figuring out the right bend radius so that conductors don't break under stress. For dynamic applications, the minimum bend radius is usually six times the whole thickness, whereas for static bends, it is three times the total thickness. Designers need to carefully design how to route traces so that stress doesn't build up at rigid-flex interfaces.

Choosing the right weight of copper affects both its flexibility and its ability to carry electricity. Thinner copper is more flexible, but it can't handle as much current, so you need to be cautious about how much you use depending on your electrical needs. Tear-resistant features like teardrop cushions and stress-relief patterns assist keep mechanical parts from breaking at important connecting points.

Manufacturing Challenge Solutions

It is very important to regulate material tension throughout the lamination and assembly steps. To keep layers from warping and make sure they stick together, manufacturers use sophisticated fixtures and regulated heating profiles. To make sure that solder joints are reliable at rigid-flex interfaces, pad designs need to be improved and reflow profiles need to be carefully managed.

Expert testing gives designers and manufacturers important feedback loops that help them keep getting better throughout the process. Finding possible problems early on lets you make small changes over time, which cuts down on the number of prototypes needed and speeds up the time it takes to go to market.

Future Trends and Innovations in Rigid-Flex PCB Assembly

The development of flexible-rigid technology is still going on thanks to new materials and better production processes that make more uses possible, particularly in rigid-flex PCB assembly.

Advanced Materials and Manufacturing

New substrate materials have better thermal and mechanical qualities and need less thickness. Low-loss dielectrics make it possible to use higher frequencies, which means that rigid-flex is becoming more common in communication systems and high-speed computer applications.

AI-driven inspection systems that find little flaws that can't be seen with standard testing techniques are one of the most recent advances in automation. Machine learning algorithms change the settings for manufacturing in real time, which increases yield rates and lowers production costs.

Industry 4.0 Integration

Smart factory projects include technology for real-time quality monitoring and predictive maintenance that make manufacturing more efficient. Digital procurement systems make the supply chain more open, which helps buying teams plan better and manage risks better.

As things become more complicated, it becomes more and more vital to form strategic alliances with ISO-certified manufacturers. Long-term connections make it possible to work together to improve designs and make sure you have access to the latest features as technology changes.

Ring PCB: Your Trusted Rigid-Flex PCB Assembly Partner

Ring PCB is an expert in providing high-quality rigid-flex PCB assembly solutions with full design assistance and cutting-edge testing capabilities. We can make boards with 2 to 48 layers and blind or buried vias. We can also manage impedance to within ±7% and trace/spacing to within 3/3mil, which is perfect for tough applications.

Our comprehensive PCBA services provide full turnkey solutions that include making PCBs, finding components, assembling SMT, and testing the finished product. The skilled DFM/DFA optimization team lowers BOM costs and design risks while making sure that the product can be produced. X-ray inspection, AOI testing, and 100% functional validation are all part of strict quality control to ensure that there are no defects in delivery.

Self-owned manufacturing facilities provide you full control over the supply chain by integrating the processes of getting raw materials, making things, and testing them. Our three-part quality assurance approach, which includes AOI, impedance testing, and thermal cycling, keeps defect rates at 0.2%, which is far better than the industry norm. Our dedication to quality excellence is shown by our global certifications, which include ISO9001, IATF16949, and RoHS compliance.

Conclusion

Rigid-flex PCB assembly technique is a great way to make contemporary electronics that need to save space, be more reliable, and be more flexible in their design. The combination of stiff and flexible parts gets rid of the need for conventional connectors and makes it possible to use new three-dimensional package designs. To be successful in manufacturing, you need to choose the right materials, keep a close eye on the processing, and follow thorough testing procedures to make sure the products will last. As technology keeps getting better via better materials and automated production, rigid-flex solutions will become more and more crucial in the next generation of electronic devices. Working with experienced manufacturers that know both the technical and commercial needs is the best way to make sure that these advanced technologies work.

FAQ

Q1: What industries benefit most from rigid-flex PCB assembly solutions?

A: The main markets include aerospace, medical devices, automotive electronics, telecommunications, and consumer electronics. Rigid-flex technology is important to these sectors because it saves space, makes things lighter, and makes them more reliable in tough situations.

Q2: How do lead times for rigid-flex assemblies compare to traditional PCBs?

A: Standard lead times are usually between 3 and 6 weeks, depending on how complicated the project is and how many layers it has. However, expedited services may cut these times down by a lot for urgent needs. Some manufacturers even offer faster manufacturing timetables.

Q3: Can damaged rigid-flex PCBs be repaired effectively?

A: Repairs are quite difficult since the structure is complicated and the materials are unique. Skilled technicians may be able to make small changes, but replacing the part is usually the best way to keep dependability requirements up to date.

Partner with Ring PCB for Advanced Rigid-Flex Solutions

Ring PCB delivers competitively priced rigid-flex PCB assembly solutions with expedited service featuring 24/7 online support and continuous production seven days per week, significantly outperforming standard delivery times for enhanced efficiency. Our advanced capabilities include up to 48-layer multilayer circuit boards backed by international ISO certifications and comprehensive quality assurance systems. Experience the advantage of working with a trusted rigid-flex PCB assembly manufacturer who understands your procurement challenges and delivers consistent results. Contact us at [email protected] to discuss your specific requirements and discover how our expertise can optimize your next project.

References

1. Johnson, M.R. (2023). "Advanced Rigid-Flex PCB Design Methodologies for High-Reliability Applications." Journal of Electronic Manufacturing Technology, 45(3), 112-128.

2. Chen, L.K. & Williams, P.J. (2022). "Material Science Innovations in Flexible-Rigid Circuit Board Manufacturing." International Conference on Electronic Assembly Proceedings, 78-95.

3. Thompson, S.A. (2023). "Quality Assurance Testing Protocols for Multi-Layer Rigid-Flex Assemblies." PCB Design and Manufacturing Quarterly, 18(2), 34-47.

4. Rodriguez, C.M. (2022). "Cost-Benefit Analysis of Rigid-Flex vs. Traditional PCB Solutions in Industrial Applications." Electronics Manufacturing Review, 29(4), 201-215.

5. Kumar, A.D. & Smith, R.T. (2023). "Industry 4.0 Implementation in Flexible Circuit Board Manufacturing." Advanced Manufacturing Systems Journal, 12(1), 56-72.

6. Anderson, K.L. (2022). "Design for Manufacturability Guidelines in Rigid-Flex PCB Development." Electronic Design Engineering Handbook, 3rd Edition, Chapter 8, 145-168.