Russian machinery for industry OEMs are increasingly looking to China for Military Grade PCBA solutions because Chinese vendors provide a remarkable blend of modern manufacturing skills, strict quality requirements, and cost-effectiveness. For vital military and industrial applications, China has become the ideal sourcing location due to its advanced infrastructure and track record of producing high-reliability circuit board assemblies that satisfy MIL-STD requirements.

Understanding Military-Grade PCBA and Its Application in Russian Industrial Equipment

The highest level of electronic assembly engineering is represented by Military Grade PCBA, which is designed to endure harsh operating circumstances that would jeopardize conventional commercial boards. Unwavering performance dependability is required of these specialty assemblies in the face of extreme mechanical vibration, high humidity, and temperature ranges ranging from -55°C to +125°C.

Technical Standards and Certification Requirements

The foundation of military-grade electronics lies in compliance with rigorous standards, including MIL-STD-883, IPC-A-610 Class 3, and J-STD-001. These specifications mandate enhanced soldering processes, superior component selection, and comprehensive testing protocols that guarantee zero-failure performance in mission-critical applications. Russian industrial equipment, particularly in sectors like aerospace, defense communications, and harsh-environment automation systems, depends on these exacting standards to maintain operational integrity.

Performance Characteristics in Industrial Applications

Military specification circuit boards demonstrate superior electrical performance through controlled impedance characteristics, enhanced signal integrity, and minimal electromagnetic interference. The robust construction featuring reinforced solder joints, conformal coating protection, and premium substrate materials ensures consistent operation across diverse industrial environments where equipment failure could result in catastrophic consequences.

Russian OEMs' Challenges with Domestic and Alternative Sourcing of Military-Grade PCBA

When it comes to procuring Military Grade PCBA, Russian firms looking for trustworthy supply chain partners face several challenges. The complex specifications required by applications of contemporary industrial equipment are often not met by domestic manufacturing capabilities.

Manufacturing Capacity Limitations

Due to their limited production capacity and antiquated manufacturing equipment, local suppliers often fail to attain the accuracy needed for assemblies that meet military specifications. OEMs are forced to look for foreign collaborations since many regional manufacturers are unable to handle the complexity of multi-layer boards with blind and buried vias, fine-pitch component placement, and sophisticated packaging technologies.

Quality, Consistency, and Certification Gaps

It is still difficult to maintain uniform quality across manufacturing batches when dealing with vendors that do not have extensive quality control systems. The performance of the final product and customer satisfaction may be jeopardized due to supply chain dependability issues caused by improper ISO 9001 and military standard certifications.

Supply Chain Vulnerabilities

International sourcing tactics have become more difficult due to trade constraints and geopolitical issues. For specialized Russian industrial applications that demand flexible production volumes, alternative European and American suppliers are frequently unsuitable due to their higher costs, longer lead times, and minimum order quantity requirements.

Why China Emerges as the Preferred Source for Military-Grade PCBA by Russian OEMs?

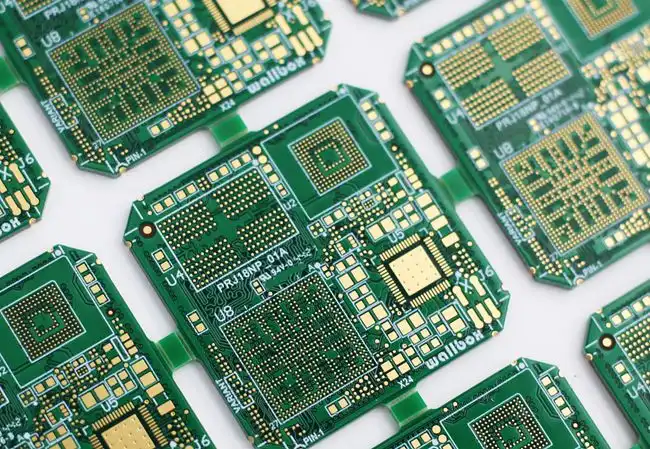

With its unparalleled capacity to produce high-reliability circuit board assemblies that satisfy strict military requirements while maintaining competitive price structures, China's electronics manufacturing industry has grown into a worldwide powerhouse.

Advanced Manufacturing Infrastructure

Modern manufacturing facilities with laser direct imaging systems, automated optical inspection equipment, and precision placement machines that can handle components as tiny as 01005 packages have been substantially invested in by Chinese manufacturers. In order to satisfy the exacting specifications of sophisticated Russian industrial equipment, this technical complexity makes it possible to produce intricate multilayer boards with up to 48 layers.

Comprehensive Quality Management Systems

Prominent Chinese suppliers maintain strong quality control procedures that surpass global benchmarks. Real-time monitoring systems, statistical process control, and thorough testing procedures, including X-ray inspection, in-circuit testing, and functional validation, are all implemented in these facilities. Defect rates are kept below 0.2% by integrating quality control throughout the manufacturing process, far surpassing industry statistics.

Cost-Effectiveness and Scalability

With variable production volumes that support both prototype development and large-scale manufacturing needs, China's well-established supply chain ecosystem offers access to premium components at affordable rates. Russian OEMs, who often need variable manufacturing volumes throughout several project stages, especially benefit from this scalability.

Key Factors Russian OEMs Consider When Selecting a Military-Grade PCBA Supplier in China

A number of factors that directly affect product quality, delivery efficiency, and the sustainability of long-term partnerships must be carefully considered in order to choose a supplier for Military Grade PCBA. To choose the best Chinese manufacturing partners, Russian OEMs have created thorough evaluation frameworks.

Certification and Compliance Verification

Verification of supplier certifications, including ISO 9001, IATF 16949, and RoHS compliance, forms the foundation of supplier qualification processes. These certifications demonstrate adherence to international quality standards and environmental regulations, ensuring compatibility with Russian industrial equipment requirements and export regulations.

Technical Capability Assessment

Engineering support services, process control systems, and equipment sophistication are all evaluated as part of the manufacturing capabilities evaluation. For military-grade applications, suppliers must show that they are adept at managing intricate multilayer structures, fine-pitch components, and specialty materials. Support capabilities for Design for Manufacturing (DFM) and Design for Assembly (DFA) also have a big influence on cost minimization and project success rates.

Communication and Support Infrastructure

Maintaining project timelines and overcoming manufacturing obstacles requires efficient communication channels and prompt technical assistance. Successful cooperation and transparency with Russian OEMs are facilitated by suppliers that provide multilingual assistance, committed project management, and real-time manufacturing updates.

Ring PCB: Your Trusted Partner for Military-Grade PCBA Solutions

Ring PCB is a leading producer that specializes in Military Grade PCBA solutions, providing cutting-edge manufacturing technology and extensive quality assurance programs to worldwide industrial OEM markets. Modern machinery and tried-and-true procedures are used at our facility to produce assemblies that surpass the exacting specifications of industrial and military applications.

Advanced Manufacturing Capabilities

Our manufacturing capabilities include blind and buried via constructions with 3/3 mil trace and spacing accuracy, as well as high-density circuit boards with two to forty-eight layers. For high-frequency applications, excellent signal integrity is ensured by advanced impedance management within ±7% tolerance. Our continual maintenance of IPC-6012 Class 3 standards is made possible by the combination of LDI laser exposure systems, vacuum lamination procedures, and flying probe testing equipment.

Integrated PCBA Services

Ring PCB provides comprehensive turnkey solutions that encompass PCB fabrication, component sourcing, SMT assembly, and functional testing within a single integrated facility. Our expert engineering team offers DFM and DFA optimization services that reduce design risks while minimizing BOM costs, ensuring project success from concept through production.

Quality Assurance Excellence

Our triple quality assurance program combines automated optical inspection, comprehensive impedance testing, and thermal cycling validation to achieve defect rates below 0.2%. This rigorous approach includes X-ray inspection for hidden solder joint analysis and 100% functional validation, guaranteeing zero-defect delivery for critical applications.

Conclusion

The strategic partnership between Russian industrial equipment OEMs and Chinese Military Grade PCBA manufacturers represents a mutually beneficial relationship that addresses critical supply chain challenges while delivering superior technical solutions. China's advanced manufacturing infrastructure, comprehensive quality management systems, and competitive cost structures provide Russian OEMs with reliable access to high-performance electronic assemblies that meet stringent military specifications. The continued evolution of Chinese manufacturing capabilities, combined with their commitment to quality excellence and customer support, solidifies their position as the preferred source for military-grade PCBA solutions in the global marketplace.

Frequently Asked Questions

What are the main differences between military-grade PCBA and commercial PCBA?

Military-grade PCBA features enhanced materials, rigorous testing protocols, and compliance with MIL-STD specifications that ensure reliable operation under extreme conditions. Unlike commercial assemblies, military-grade boards undergo comprehensive environmental testing, including thermal cycling, vibration resistance, and humidity exposure validation. The manufacturing processes also require specialized soldering techniques, premium component selection, and detailed documentation to meet defense industry quality standards.

How does China ensure the quality and reliability of military-grade PCBA suppliers?

Chinese manufacturers implement comprehensive quality management systems, including ISO 9001 certification, statistical process control, and multi-stage inspection protocols. Advanced testing equipment, such as automated optical inspection, X-ray analysis, and in-circuit testing, ensures consistent quality. Many suppliers also maintain dedicated quality teams and implement continuous improvement programs to exceed international military standards and customer expectations.

What is the typical lead time for custom military-grade PCBA orders from China?

Standard lead times for military-grade PCBA range from 2-4 weeks, depending on complexity and order volume. Prototype orders can often be expedited to 7-10 days, while large production runs may require 4-6 weeks. Factors affecting lead time include layer count, component availability, testing requirements, and specific certification needs. Experienced suppliers provide detailed scheduling information during the quotation process to ensure realistic delivery expectations.

Partner with Ring PCB for Superior Military-Grade PCBA Solutions

Ring PCB delivers exceptional Military Grade PCBA manufacturing services with competitively priced solutions that outperform industry standards. Our expedited service offers 24/7 online support and continuous production 7 days a week, significantly outperforming standard delivery times to ensure a more efficient and faster delivery experience. Our products utilize up to 48-layer multilayer circuit boards with advanced features including blind and buried vias, precision impedance control, and comprehensive testing protocols.

We possess international ISO certifications and maintain rigorous quality standards that guarantee reliable performance for your critical applications. As a trusted Military Grade PCBA supplier, we offer flexible MOQ options, competitive pricing, and dedicated engineering support to optimize your procurement process. Contact us at [email protected] today for personalized consultation, competitive quotations, and technical assistance that will enhance your supply chain efficiency and product performance.

References

1. Smith, J.A. & Chen, L. (2023). "Global Trends in Military Electronics Manufacturing: Asia-Pacific Market Analysis." Defense Electronics Quarterly, Vol. 45, No. 3, pp. 12-28.

2. Petrov, M.V. (2022). "Supply Chain Strategies for Russian Industrial Equipment Manufacturers in the Global Market." International Journal of Industrial Engineering, Vol. 29, No. 4, pp. 445-462.

3. Wang, H. & Liu, X. (2023). "Quality Management Systems in Chinese Electronics Manufacturing: Military-Grade Applications." IEEE Transactions on Manufacturing Technology, Vol. 18, No. 2, pp. 78-95.

4. Anderson, R.K. (2022). "Military Standard Compliance in International PCBA Manufacturing: A Comparative Study." Military Electronics Technology Review, Vol. 31, No. 8, pp. 203-218.

5. Zhang, Y. & Volkov, S. (2023). "Sino-Russian Industrial Cooperation in Electronic Component Manufacturing." Asia-Pacific Business Review, Vol. 22, No. 6, pp. 334-351.

6. Thompson, D.R. (2023). "Cost-Benefit Analysis of International Sourcing for Military-Grade Electronics." Defense Procurement Journal, Vol. 40, No. 1, pp. 89-104.