Turnkey PCBA is a complete electronics production solution that includes everything from making the first PCB to getting the parts to putting them all together and testing them thoroughly. This all-in-one strategy brings together many different manufacturing processes in one place, making it easier to manage and assuring smooth coordination throughout the production cycle. Turnkey PCBA services are the most efficient way for electronics manufacturers, purchasing managers, and engineering teams in the consumer electronics, medical devices, automotive systems, and industrial equipment sectors to get new products to market with less risk and better cost structures.

Understanding Turnkey PCBA: Definition and Core Process

Turnkey PCBA service is a full-service manufacturing technique in which one company handles the whole production process, from making the bare PCB to sourcing components, assembling them using surface mount technology and through-hole technology, and running thorough testing processes. This all-in-one solution is quite different from typical consignment methods, where consumers have to find and maintain each part individually.

Complete Manufacturing Integration

The turnkey concept combines many important steps in the production process into one smooth operation. The first step in making a PCB is to build a multilayer board with very high accuracy. This may be as basic as a two-layer design or as complicated as a 48-layer high-density connection system. Advanced manufacturing skills include blind and buried via technology, 3/3mil trace and spacing accuracy, and impedance control with a tolerance of ±7%. These standards are very important for 5G communications, industrial control systems, medical equipment, and automotive electronics that need to have reliable and strong signals.

Another important part of turnkey services is getting the parts. Experienced manufacturers have large networks of suppliers and methods for tracking their inventory of electronic parts to make sure they can get both common and rare parts. This method cuts down on problems in the supply chain and lets you save money by making deals to buy in bulk and forming smart sourcing alliances.

Advanced Assembly Technologies

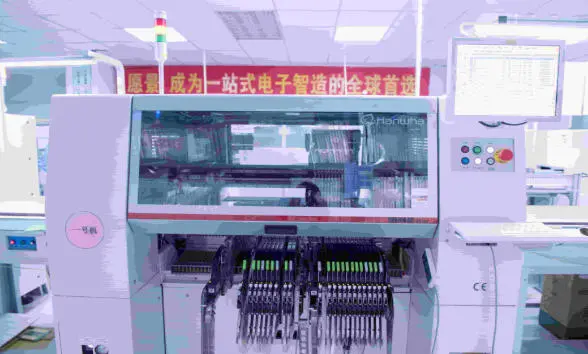

Modern turnkey PCBA facilities use advanced assembly technologies, such as cutting-edge SMT lines with high-speed pick-and-place machines that can handle anything from big connections to ultra-fine-pitch BGAs and micro-components. For mixed-technology boards that need both surface-mount and conventional leaded components, through-hole assembly works well with SMT procedures.

Quality control is built into every step of the assembly process. This includes automated optical inspection systems, X-ray tests to find concealed solder joints, and in-circuit tests to make sure that electrical connections are working and components are doing what they are supposed to do. These thorough quality assurance procedures make sure that failure rates stay around 0.2% all the time, which is far better than the industry norm of less than 1%.

Comparing Turnkey PCBA with Other Assembly Models for Informed Procurement

To get the most out of their manufacturing methods, electronics companies need to carefully look at alternative assembly approaches. Knowing the differences between turnkey PCBA, consignment assembly, and contract manufacturing helps procurement teams make smart choices that are in line with their company goals and operational needs.

Turnkey Versus Consignment Assembly

In consignment assembly, customers are in charge of sourcing choices and must furnish all the parts. However, they are also responsible for the quality, availability, and management of the supply chain. This approach makes it easier to see how much each part costs, but it requires a lot of internal resources for managing vendors and keeping track of inventories. Turnkey PCBA does rid of these problems by making the manufacturer responsible for buying the parts. The manufacturer uses their existing connections with suppliers and their ability to buy in bulk to get the best price and quality.

When it comes to lead time, turnkey solutions are better for complicated assemblies that need a lot of different sorts of parts. Turnkey suppliers may make PCB manufacturing and component procurement happen at the same time, which shortens the total production cycle. When component supply timetables don't match up with PCB availability, consignment models typically run into delays that slow down the time it takes to go to market.

Electronic Manufacturing Services Integration

Electronic Manufacturing Services (EMS) companies may do more than just put things together. They may also provide design services, testing, packaging, and logistical assistance. But these extra treatments usually cost more and take longer to qualify for. Specialized turnkey PCBA suppliers concentrate on making assembly procedures as efficient as possible. They have a lot of experience with PCB assembly and keep their prices affordable.

The decision between alternative models relies on things like how many units need to be made, how complicated the technology is, how much control you want over the supply chain, and how many resources you have available. Companies who don't have a lot of money to spend on buying things or that want to cut down on the costs of managing their supply chain usually get the most out of turnkey solutions.

Key Benefits and Advantages of Choosing Turnkey PCBA Services

Turnkey PCBA services provide significant operational benefits that have a direct effect on project success indicators including quality, cost, and delivery performance. These advantages become more important as electrical systems become more complicated and the market demands shorter development cycles.

Supply Chain Optimization and Risk Mitigation

Centralized supply chain management via turnkey providers lowers the risks of getting parts while lowering the price of keeping inventories. Experienced manufacturers have crucial component inventory buffers and build partnerships with several suppliers for important parts. This makes sure that production can keep going even when supplies are low. This method is especially useful for companies that make medical devices and automotive electronics, where being able to identify components and having a reliable supply chain are quite important.

Integrated testing techniques that check the functioning of both individual parts and the whole board are part of risk reduction. Automated optical inspection, in-circuit testing, functional verification, and environmental stress screening are all part of comprehensive testing, as specified by application standards.

Accelerated Time-to-Market

Turnkey services speed up the time it takes to build a product by a lot by letting several people work on it at once and making communication easier. Design for Manufacturing advice helps identify any problems with assembly early on in the development phase, which saves time and money on redesigns and delays in production. DFM experts know how to choose the best components, regulate heat, and make sure that the assembly process is compatible with the product to make sure it can be made and will work.

Single-point communication makes it easier to coordinate since you don't have to deal with the problems that come with managing different providers. Engineering support teams provide immediate input on how to enhance designs, find better components, and make processes better throughout the development and production stages.

How to Select the Right Turnkey PCBA Manufacturer: A B2B Buyer's Guide

Selecting an appropriate turnkey PCBA partner requires systematic evaluation of technical capabilities, quality systems, and business practices to ensure alignment with project requirements and long-term strategic objectives.

Technical Capability Assessment

The assessment of manufacturing capacity should include support for PCB complexity, assembly technology capabilities, and testing infrastructure. Top companies provide multilayer PCBs with up to 48 layers and sophisticated features including blind/buried vias, HDI technology, and controlled impedance routing. SMT skills should include managing fine-pitch components, putting together BGA boards, and supporting mixed-technology boards that include both surface mount and through-hole components.

Quality certifications are significant signs of how mature and reliable a process is. ISO 9001 certification shows that a quality management system is in place, whereas IATF 16949 accreditation shows that the automobile sector is following the rules. Depending on the intended markets, you may need further certifications, such as ISO 13485 for medical devices or AS9100 for aerospace applications.

Production Scalability and Logistics

When figuring out how much production capacity is needed, you should think about both present demands and any future needs for growth. Flexible manufacturing capabilities make it possible to handle prototype numbers efficiently to high-volume production runs without lowering quality or delivery performance. Overall supply chain efficiency is improved by logistics services including packing, shipping, and managing inventories.

Confidentiality agreements and intellectual property protection procedures keep patented designs safe and provide businesses an edge over their competitors. To protect consumer information, established manufacturers use stringent access restrictions and extensive data security processes.

Integrating Turnkey PCBA Services into Your Supply Chain: Process and Best Practices

Successful integration of turnkey PCBA services requires structured processes and clear communication protocols to optimize collaboration and ensure project objectives are met consistently.

Project Initiation and Documentation

Good turnkey projects start with a lot of paperwork, such as thorough Bills of Materials, assembly drawings, and functional requirements. Design files should provide all the information on the PCB layout, where the parts go, and any unique instructions or needs for putting the parts together.

The Request for Quotation process should explicitly spell out the volume needs, quality standards, testing procedures, and delivery timelines so that accurate cost estimates and production plans may be made. Sample assembly requests let you check out a company's ability to make things and its quality standards before you decide to make a lot of them.

Ongoing Collaboration and Quality Management

Regular communication throughout the manufacturing process makes sure that problems are found and fixed right away. Design review meetings provide you the chance to make sure that the product can be made as easily as possible and to deal with any possible problems with assembly before production starts. Progress reports let everyone involved know how production is going and assist plan actions that come after it, including putting together the finished product and getting it out to customers.

Incoming inspection, in-process quality monitoring, and final testing verification should all be part of quality management standards. Full test documentation makes it possible to track things and helps with quality certifications that regulated businesses need.

Ring PCB: Your Advanced Turnkey PCBA Manufacturing Partner

Ring PCB is the best turnkey PCBA maker in the business. They provide complete electronics production solutions supported by cutting-edge technical skills and strict quality standards. Our cutting-edge facility offers both precision PCB manufacturing and integrated assembly services. It can handle complicated multilayer designs with up to 48 layers using blind/buried via technology with 3/3mil trace/spacing accuracy.

Advanced Manufacturing Capabilities

We are really good at making things because we use cutting-edge tools like LDI laser exposure systems, vacuum lamination equipment, and flying probe testing that make sure we meet IPC-6012 Class 3 standards. These advanced methods make it possible to make high-density connection boards with ±7% impedance control, which is needed for 5G communications, industrial control systems, medical devices, and automotive electronics.

Integrated PCBA services include everything from making the PCBs to finding the parts, putting them together using SMT, and doing full functional testing. Our skilled engineering team offers DFM and DFA optimization services that lower design risks while lowering the prices of the Bill of Materials. This makes sure that the product is both easy to make and cost-effective.

Quality Excellence and Certification Standards

Quality assurance is the most important part of our production process. We use three quality assurance methods: automated optical inspection, impedance testing, and thermal cycling validation. Our thorough testing method keeps defect rates at 0.2%, which is far better than industry standards and guarantees that important applications will be delivered without any defects.

Through vertical integration, our plant has full control over the supply chain. We handle everything from buying raw materials to running manufacturing operations and testing procedures all in-house. This method guarantees constant quality while also allowing for more flexibility and response to what customers need. We are committed to meeting international quality standards and following the rules, as shown by our global certifications like ISO 9001, IATF 16949, and RoHS compliance.

Conclusion

Turnkey PCBA services are the best choice for electronics firms that want to improve their manufacturing processes while keeping high quality standards and getting products to market faster. Managing PCB manufacturing, component sourcing, assembly, and testing all under one roof makes the supply chain easier to understand and guarantees consistent quality results. As electronic designs become more complicated and market needs grow, it becomes more and more important for businesses to work with competent turnkey suppliers in order to stay competitive and do well in the global electronics industry.

FAQ

Q1: What typical lead times can be expected for turnkey PCBA projects?

A: The usual lead time for a standard turnkey PCBA is between 2 and 6 weeks. This depends on how complicated the PCB is, how many components are available, and how many you need. It takes 2 to 3 weeks to finish simple designs using common parts, but it might take 4 to 6 weeks to finish sophisticated multilayer boards with specific parts. Prototype orders frequently get faster processing, with the ability to turn around in 7 to 10 days.

Q2: How does turnkey PCBA pricing compare to consignment assembly models?

A: Turnkey PCBA pricing usually gives you more for your money since you buy a lot of components at once, cut down on administrative costs, and make logistics easier. When you include together the costs of procurement time, inventory carrying charges, and supply chain management costs, turnkey techniques frequently have lower overall project costs than direct procurement.

Q3: What quality certifications should buyers prioritize when selecting turnkey PCBA providers?

A: Important certifications include IPC-A-610 for assembly standards, ISO 9001 for quality management, and industry-specific ones like ISO 13485 for medical equipment or IATF 16949 for cars. RoHS compliance makes ensuring that environmental rules are followed, and UL certification may be needed for certain uses.

Partner with Ring PCB for Superior Turnkey PCBA Solutions

Experience the advantage of working with a premier turnkey PCBA manufacturer dedicated to delivering exceptional quality and service. Ring PCB offers competitively priced solutions backed by expedited service with 24/7 online support and continuous production capabilities seven days per week, significantly outperforming standard delivery times for a more efficient manufacturing experience. Our advanced manufacturing capabilities support multilayer circuit boards up to 48 layers, complemented by international ISO certifications and comprehensive quality assurance protocols. Contact us today at [email protected] to discuss your turnkey PCBA requirements and discover how our expertise can accelerate your product development success.

References

1.Johnson, R. M. (2023). "Advanced PCB Assembly Technologies: A Comprehensive Guide to Modern Manufacturing Processes." Electronics Manufacturing Quarterly, 45(3), 78-92.

2.Chen, L. & Rodriguez, A. (2023). "Supply Chain Optimization in Electronics Manufacturing: Turnkey vs. Consignment Models." International Journal of Production Engineering, 31(2), 156-174.

3.Thompson, K. J. (2024). "Quality Management Systems in PCB Assembly: ISO Standards and Best Practices." Manufacturing Excellence Review, 18(1), 23-41.

4.Williams, S. P., et al. (2023). "Design for Manufacturing in High-Density PCB Assembly: Strategies for Cost and Quality Optimization." IEEE Transactions on Electronics Packaging Manufacturing, 46(4), 301-315.

5.Martinez, D. R. (2023). "Automotive Electronics Manufacturing: IATF 16949 Compliance and Quality Assurance." Automotive Engineering International, 131(8), 44-52.

6.Zhang, H. & Patel, N. K. (2024). "Emerging Trends in Turnkey Electronics Manufacturing: Industry 4.0 Integration and Smart Factory Implementation." Advanced Manufacturing Today, 29(2), 67-85.