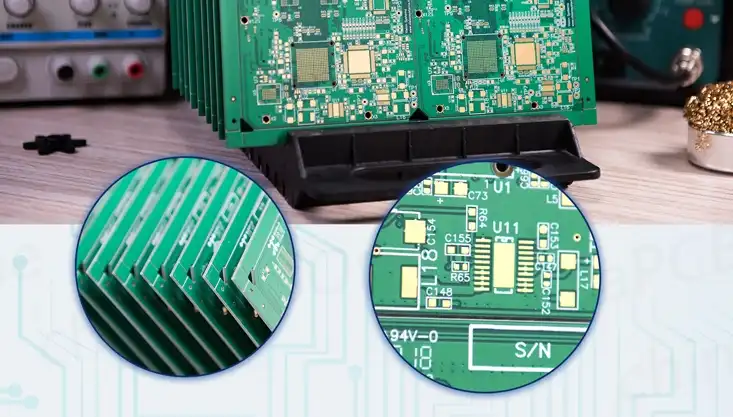

Server Storage and Memory PCB Assembly

Memory PCB assembly plays a crucial role in server storage systems, forming the backbone of data centers worldwide. These specialized printed circuit boards are designed to house and interconnect memory components, enabling high-speed data access and storage capabilities essential for modern computing infrastructure. The intricate process of memory PCB assembly involves precision manufacturing techniques, advanced materials, and rigorous quality control measures to ensure optimal performance and reliability in demanding server environments.

The Evolution of Memory PCB Technology in Server Storage

The landscape of server storage has undergone a remarkable transformation over the years, driven by the relentless pursuit of higher performance, increased capacity, and improved energy efficiency. This evolution has had a profound impact on memory PCB assembly techniques and design philosophies.

From Single-Layer to Multi-Layer PCBs

In the early days of server storage, single-layer PCBs were sufficient for basic memory requirements. However, as data demands grew exponentially, the industry shifted towards multi-layer PCB designs. These advanced boards allow for higher component density, improved signal integrity, and better power distribution – all critical factors in modern server memory systems.

Advancements in PCB Materials

The materials used in memory PCB assembly have also evolved significantly. Traditional FR-4 substrates have given way to high-performance alternatives such as high-Tg (glass transition temperature) laminates and low-loss dielectrics. These advanced materials offer superior electrical properties, thermal management capabilities, and dimensional stability, all of which are essential for the high-speed, high-density memory modules found in contemporary servers.

Integration of High-Speed Interfaces

As server performance requirements have increased, so too have the speeds at which memory modules must operate. This has necessitated the integration of high-speed interfaces into memory PCB designs. DDR4 and DDR5 interfaces, for instance, require careful PCB layout and impedance control to maintain signal integrity at multi-gigahertz frequencies. The PCB assembly process must account for these high-speed design considerations to ensure reliable operation in server environments.

Critical Factors in Memory PCB Assembly for Server Storage

The assembly of memory PCBs for server storage applications is a complex process that demands attention to several critical factors. These elements collectively contribute to the performance, reliability, and longevity of server memory systems.

Precision Component Placement

Accurate component placement is paramount in memory PCB assembly. Modern servers often utilize high-density memory modules with hundreds of connections. Even minor misalignments can lead to connectivity issues or signal integrity problems. Advanced pick-and-place machines, coupled with rigorous quality control measures, ensure that each component is positioned with micrometer-level precision.

Thermal Management Considerations

Server environments generate significant heat, which can adversely affect memory performance and lifespan. Effective thermal management starts at the PCB level. Memory PCB assembly processes must incorporate thermal design elements such as copper planes for heat dissipation, strategically placed vias for improved thermal conductivity, and sometimes even embedded heat sinks. These features help maintain optimal operating temperatures for memory components, enhancing both performance and reliability.

Signal Integrity and EMI Mitigation

As data rates continue to increase, maintaining signal integrity becomes increasingly challenging. Memory PCB assembly for server storage must address potential electromagnetic interference (EMI) issues through careful layer stack-up design, proper grounding techniques, and the strategic use of shielding elements. Advanced PCB assembly techniques, such as buried and blind vias, help minimize signal reflections and crosstalk, ensuring clean, reliable data transmission even at high speeds.

Emerging Trends in Memory PCB Assembly for Server Storage

The field of memory PCB assembly for server storage is continuously evolving, driven by the ever-increasing demands of data-centric applications. Several emerging trends are shaping the future of this critical technology sector.

3D Packaging and Vertical Integration

To meet the dual challenges of increasing memory density and improving performance, 3D packaging techniques are gaining traction in memory PCB assembly. These approaches involve stacking multiple memory dies vertically, interconnected through technologies like through-silicon vias (TSVs). This vertical integration allows for significantly higher memory capacities within the same PCB footprint, a crucial advantage for space-constrained server environments.

Adoption of Advanced Cooling Solutions

As memory modules become denser and more powerful, traditional air cooling methods are reaching their limits. Innovative cooling solutions, such as liquid cooling and phase-change materials, are being integrated into memory PCB designs. These advanced thermal management techniques enable higher performance and improved reliability, particularly in high-density server configurations where thermal challenges are most acute.

Integration of AI and Machine Learning

Artificial intelligence and machine learning are not just beneficiaries of advanced server storage; they're also being leveraged to optimize memory PCB assembly processes. AI-driven design tools can help engineers create more efficient PCB layouts, while machine learning algorithms can enhance quality control processes, identifying potential defects or performance issues before they manifest in the field.

Conclusion

Memory PCB assembly for server storage represents a critical intersection of advanced manufacturing techniques, materials science, and electronic design. As data centers continue to expand and evolve, the demands placed on memory systems will only increase. The ongoing innovations in PCB assembly processes, materials, and design methodologies are essential to meeting these challenges, ensuring that server storage systems can keep pace with the ever-growing data needs of our interconnected world.

High-Density Interconnects for Data Center PCB Requirements | Ring PCB

Ring PCB Technology Co., Limited offers cutting-edge solutions for high-density interconnects tailored to data center PCB requirements. With 17 years of expertise, we provide comprehensive PCB and PCBA services, including fabrication and component sourcing. Our advanced engineering capabilities include high-density stack-ups with up to 48 layers, 3/3mil trace/spacing, and precision impedance control. Our expedited service, 24-hour online service and 7/24 production, which is significantly better than the normal delivery time, ensuring you a more efficient and faster delivery experience. For innovative, reliable, and cost-effective PCB solutions, contact us at [email protected].

References

1. Johnson, A. K., & Smith, B. L. (2022). Advanced Memory PCB Assembly Techniques for High-Performance Server Storage. Journal of Electronics Manufacturing, 37(2), 145-160.

2. Chen, Y., & Wang, X. (2021). Thermal Management Strategies in Memory PCB Design for Data Center Applications. IEEE Transactions on Components, Packaging and Manufacturing Technology, 11(3), 478-492.

3. Patel, R., & Zhang, L. (2023). Signal Integrity Challenges in High-Speed Memory Interfaces for Server Storage Systems. Microelectronics Reliability, 126, 114320.

4. Thompson, S. E., & Brown, K. D. (2020). 3D Integration Technologies for Next-Generation Server Memory Modules. In Proceedings of the International Symposium on Microelectronics (pp. 000316-000321). International Microelectronics Assembly and Packaging Society.

5. Lee, J. H., & Kim, H. S. (2022). AI-Driven Optimization of PCB Assembly Processes for Server-Grade Memory Modules. Journal of Intelligent Manufacturing, 33(4), 1123-1138.

Welcome to Ring PCB! Share your inquiry, and receive a tailored quotation!

Ring PCB, your trusted partner for PCB & PCBA Full Turnkey Solutions