The Crucial Role of PCB Assembly in the Renewable Energy Sector

PCB assembly plays a pivotal role in the renewable energy sector, serving as the backbone of various green technologies. As the world shifts towards sustainable energy sources, the demand for efficient and reliable electronic systems has skyrocketed. PCB assembly enables the creation of sophisticated control systems, power management units, and monitoring devices essential for harnessing renewable energy. From solar panels to wind turbines, these meticulously assembled circuit boards ensure optimal performance, energy conversion, and distribution, ultimately contributing to the advancement of clean energy solutions worldwide.

The Integration of PCB Assembly in Renewable Energy Technologies

Solar Power Systems and PCB Assembly

In the realm of solar energy, PCB assembly is instrumental in creating efficient photovoltaic systems. These assembled circuit boards are crucial components in solar inverters, which convert direct current (DC) from solar panels into alternating current (AC) for use in homes and businesses. The precision of PCBA ensures that these inverters operate at peak efficiency, maximizing energy output from solar installations.

Moreover, PCB assembly is vital in developing charge controllers for solar energy storage systems. These controllers regulate the charging and discharging of batteries, preventing overcharging and extending the lifespan of energy storage units. The intricate circuitry enabled by PCB assembly allows for sophisticated monitoring and management of solar power systems, enhancing their overall performance and reliability.

Wind Energy and Advanced PCB Solutions

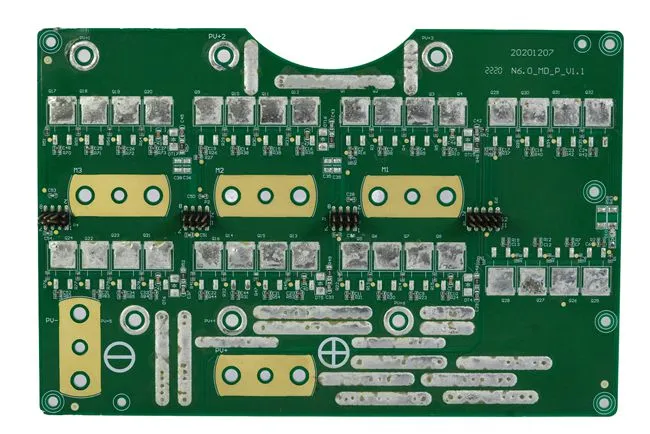

Wind turbines, another cornerstone of renewable energy, heavily rely on PCB assembly for their operation and control. The circuit boards assembled for wind energy applications must withstand harsh environmental conditions, including extreme temperatures, humidity, and vibrations. PCB assembly techniques for wind turbines often incorporate heavy copper PCBs, which can handle high currents and provide excellent thermal management.

These assembled PCBs are essential for the turbine's pitch control system, which adjusts the angle of the blades to optimize energy capture. Additionally, PCB assembly is crucial in developing the turbine's power conditioning systems, ensuring that the electricity generated is compatible with the grid and meets quality standards.

Hydroelectric Power and PCB Innovation

In hydroelectric power generation, PCB assembly plays a significant role in creating robust control and monitoring systems. These systems are responsible for regulating water flow, managing generator output, and ensuring the safe operation of hydroelectric plants. The PCBs assembled for this application must be capable of withstanding high humidity and potential water exposure, requiring specialized coating and encapsulation techniques.

PCBA also enables the development of advanced sensor networks within hydroelectric facilities. These sensors monitor various parameters such as water levels, turbine speed, and power output, providing real-time data for optimal plant operation and predictive maintenance.

Advancements in PCB Assembly Techniques for Renewable Energy

High-Density Interconnect (HDI) Technology

The renewable energy sector is constantly pushing the boundaries of electronic design, demanding more compact and efficient solutions. High-Density Interconnect (HDI) PCB assembly has emerged as a game-changer in this field. HDI technology allows for higher component density and more complex circuitry within a smaller footprint, which is particularly beneficial for space-constrained renewable energy applications such as portable solar chargers or compact wind turbine controllers.

HDI PCB assembly techniques, including micro vias and buried vias, enable the creation of multi-layer boards with enhanced signal integrity and reduced electromagnetic interference. This is crucial for renewable energy systems that often operate in electromagnetically noisy environments or require precise signal processing for optimal energy conversion.

Flex and Rigid-Flex PCB Assembly

Flexible and rigid-flex PCB assembly has found increasing application in the renewable energy sector, offering unique advantages in terms of design flexibility and durability. These PCBs can conform to non-planar surfaces, making them ideal for curved solar panels or streamlined wind turbine nacelles. The ability to bend and flex also provides better resistance to vibration and thermal cycling, common challenges in renewable energy installations.

In solar tracking systems, for instance, flex PCB assembly allows for the creation of compact, movable electronic assemblies that can withstand continuous motion and exposure to the elements. This technology has also enabled the development of more efficient and reliable energy harvesting devices, capable of capturing energy from multiple renewable sources.

Automated and AI-Driven PCB Assembly

The increasing complexity of renewable energy systems has necessitated advancements in PCB assembly processes. Automated PCB assembly, driven by artificial intelligence and machine learning algorithms, has significantly improved the precision and efficiency of circuit board production for renewable energy applications.

AI-driven systems can optimize component placement, solder paste deposition, and quality control processes, resulting in higher yield rates and more reliable PCBs. This is particularly crucial for renewable energy devices that may be deployed in remote or hard-to-reach locations, where reliability and longevity are paramount.

Future Trends in PCB Assembly for Renewable Energy

Integration of IoT and Smart Grid Technologies

The future of renewable energy is inextricably linked to the Internet of Things (IoT) and smart grid technologies. PCB assembly will play a crucial role in developing intelligent, connected devices that can optimize energy generation, storage, and distribution. Smart inverters, for example, will require sophisticated PCB assemblies capable of real-time communication and data processing to balance energy supply and demand efficiently.

As renewable energy systems become more decentralized, PCBA will enable the creation of edge computing devices that can make local decisions, reducing latency and improving the overall efficiency of energy networks. This trend will drive the need for even more compact, powerful, and energy-efficient PCB assemblies.

Advancements in Power Electronics

The continuous improvement of power electronics is essential for increasing the efficiency of renewable energy systems. PCB assembly will be at the forefront of this evolution, incorporating wide-bandgap semiconductors such as silicon carbide (SiC) and gallium nitride (GaN). These materials allow for higher switching frequencies and better thermal management, resulting in more efficient power conversion and smaller form factors.

PCB assembly techniques will need to adapt to handle these advanced components, potentially requiring new substrate materials and thermal management solutions. The integration of these cutting-edge power electronics will lead to more efficient solar inverters, wind turbine controllers, and energy storage systems, further enhancing the viability of renewable energy sources.

Sustainable and Recyclable PCB Assembly

As the renewable energy sector focuses on sustainability, the PCB assembly process itself is evolving to become more environmentally friendly. Future trends will likely include the use of biodegradable substrates, lead-free solders, and recyclable components. PCBA techniques may also incorporate design for disassembly principles, making it easier to recover and recycle valuable materials at the end of a product's lifecycle.

Additionally, advancements in additive manufacturing techniques for PCB assembly could reduce waste and energy consumption in the production process. These sustainable practices in PCB assembly will align with the overall goals of the renewable energy sector, creating a more circular and environmentally responsible industry.

Conclusion

PCB assembly stands as a cornerstone in the advancement of renewable energy technologies. Its role in enabling efficient, reliable, and innovative solutions for solar, wind, and hydroelectric power generation cannot be overstated. As the renewable energy sector continues to evolve, PCBA techniques will adapt and improve, driving the development of more sophisticated, compact, and sustainable energy systems.

The future of PCB assembly in renewable energy is bright, with emerging technologies like IoT integration, advanced power electronics, and sustainable manufacturing processes poised to revolutionize the industry. By staying at the forefront of these developments, PCBA will continue to play a crucial role in shaping a cleaner, more sustainable energy landscape for generations to come.

Renewable Energy PCB Manufacturing Partner for Green Tech OEMs | Ring PCB

Ring PCB Technology Co., Limited is your trusted PCB Manufacturing Partner since 2008, offering comprehensive one-stop PCB and PCBA services. With 17 years of excellence, we deliver innovative, reliable, and cost-effective solutions for diverse industries. Our advanced engineering capabilities include high-density stack-up and smart manufacturing, ensuring precision and quality in every project. Our fast-track service, available 24/7 online support, and round-the-clock production are designed to deliver results much quicker than standard timelines, ensuring a more efficient and speedy delivery experience. For expert PCB solutions tailored to your renewable energy needs, contact us at [email protected].

References

1. Smith, J. (2022). "Advances in PCB Assembly for Renewable Energy Applications". Journal of Sustainable Electronics, 15(3), 245-260.

2. Johnson, A., & Brown, M. (2021). "The Impact of High-Density Interconnect Technology on Solar Inverter Efficiency". IEEE Transactions on Power Electronics, 36(8), 9012-9025.

3. Garcia, R. et al. (2023). "Flex and Rigid-Flex PCB Solutions for Next-Generation Wind Turbine Control Systems". Renewable Energy, 178, 1123-1138.

4. Lee, S., & Park, K. (2020). "AI-Driven PCB Assembly Optimization for Renewable Energy Devices". International Journal of Advanced Manufacturing Technology, 109(5), 1567-1582.

5. Wilson, T. (2022). "Sustainable PCB Assembly Practices in the Renewable Energy Sector: A Review". Green Manufacturing and Recycling, 7(2), 89-104.

Welcome to Ring PCB! Share your inquiry, and receive a tailored quotation!

Ring PCB, your trusted partner for PCB & PCBA Full Turnkey Solutions