What is a PCBA in medical terms?

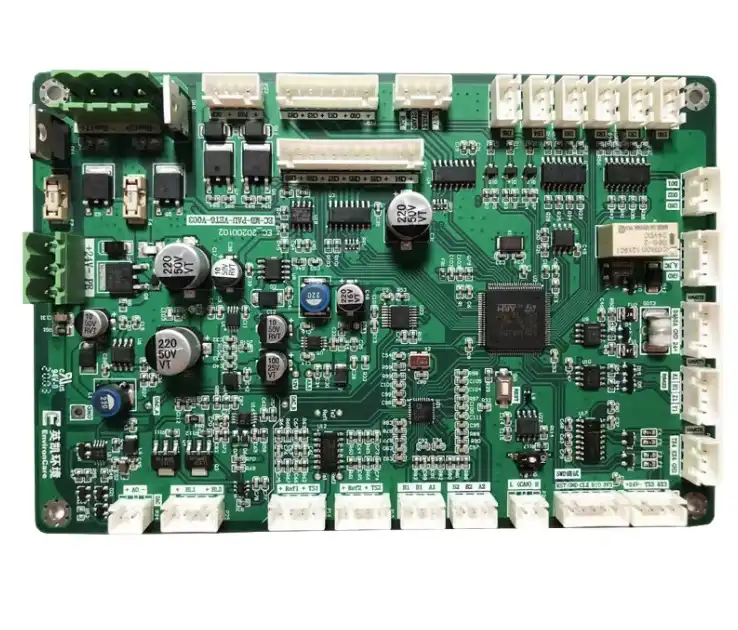

In medical terms, a PCBA (Printed Circuit Board Assembly) refers to a fully assembled electronic circuit board used in various medical devices and equipment. It's the heart of medical technology, integrating electronic components onto a printed circuit board to create functional systems for diagnostics, monitoring, and treatment. Medical Equipment PCBAs are specialized assemblies designed to meet stringent healthcare industry standards, ensuring reliability, precision, and safety in critical medical applications. These assemblies play a crucial role in powering everything from simple medical monitors to complex imaging systems and life-support equipment.

The Crucial Role of PCBAs in Medical Equipment

Medical Equipment PCBAs serve as the backbone of modern healthcare technology, powering a wide array of devices that are indispensable in patient care and medical research. These specialized assemblies are meticulously designed and manufactured to meet the exacting standards of the medical industry, ensuring optimal performance and reliability in critical healthcare settings.

Applications of PCBAs in Medical Devices

The versatility of PCBAs in medical equipment is truly remarkable. They are found in a diverse range of devices, each serving a unique purpose in healthcare:

- Diagnostic Imaging Systems: MRI machines, CT scanners, and ultrasound devices rely on sophisticated PCBAs to process and display high-resolution images.

- Patient Monitoring Equipment: Vital sign monitors, ECG machines, and pulse oximeters use PCBAs to accurately measure and display patient data.

- Therapeutic Devices: Infusion pumps, defibrillators, and radiation therapy equipment incorporate PCBAs for precise control and safety mechanisms.

- Laboratory Equipment: PCR machines, blood analyzers, and spectrophotometers utilize PCBAs for accurate sample analysis and result interpretation.

- Wearable Medical Devices: Continuous glucose monitors, smart insulin pumps, and cardiac event recorders employ compact PCBAs for real-time health monitoring.

Key Features of Medical Equipment PCBAs

Medical Equipment PCBAs are distinguished by several key features that set them apart from standard electronic assemblies:

- High Reliability: Designed to operate consistently in critical healthcare environments, often with redundant systems to prevent failures.

- Precision: Engineered for extreme accuracy in measurement and control, crucial for diagnostic and therapeutic applications.

- Biocompatibility: Constructed using materials that are safe for use in close proximity to or inside the human body.

- EMI/RFI Shielding: Incorporates robust electromagnetic and radio frequency interference protection to ensure accurate readings and prevent interference with other medical devices.

- Thermal Management: Features advanced cooling solutions to maintain optimal operating temperatures, even in continuous use scenarios.

- Compact Design: Optimized for space efficiency, allowing for the miniaturization of medical devices without compromising functionality.

- Compliance with Medical Standards: Adheres to stringent regulatory requirements such as ISO 13485, IEC 60601, and FDA guidelines.

These features collectively ensure that Medical Equipment PCBAs meet the high standards required for use in healthcare settings, where reliability and precision are paramount.

Manufacturing Processes and Quality Control for Medical PCBAs

The production of Medical PCBAs involves a series of sophisticated manufacturing processes and rigorous quality control measures. These steps are crucial in ensuring the reliability and performance of medical devices that rely on these assemblies.

Advanced Manufacturing Techniques

The manufacturing of Medical Equipment PCBAs employs cutting-edge techniques to achieve the highest standards of quality and precision:

- Surface Mount Technology (SMT): Allows for high-density component placement, crucial for creating compact medical devices.

- Through-Hole Technology: Used for components that require stronger mechanical bonds, ensuring durability in portable medical equipment.

- Automated Optical Inspection (AOI): Utilizes high-resolution cameras and advanced algorithms to detect defects invisible to the human eye.

- X-ray Inspection: Enables inspection of hidden solder joints and internal layers of multilayer PCBs, crucial for complex medical devices.

- Conformal Coating: Applies a protective layer to shield the PCBA from moisture, dust, and chemicals, enhancing longevity and reliability.

- Selective Soldering: Allows precise soldering of through-hole components on boards with surface mount devices, maintaining thermal sensitivity.

Stringent Quality Control Measures

Quality control in the production of Medical Equipment PCBAs is paramount, involving multiple layers of testing and validation:

- In-Circuit Testing (ICT): Verifies the electrical integrity of each component and connection on the PCBA.

- Functional Testing: Simulates real-world operating conditions to ensure the PCBA performs as intended in the final medical device.

- Environmental Stress Screening: Subjects PCBAs to extreme temperatures and vibrations to identify potential weaknesses or defects.

- Reliability Testing: Includes accelerated life testing and HALT (Highly Accelerated Life Testing) to predict long-term performance and identify potential failure modes.

- Traceability: Implements comprehensive component and process traceability to facilitate recalls and continuous improvement.

- Clean Room Assembly: Utilizes controlled environments to minimize contamination during the assembly process.

These rigorous quality control measures ensure that Medical Equipment PCBAs meet or exceed the stringent requirements of the healthcare industry, providing healthcare professionals with reliable and accurate tools for patient care.

Future Trends and Innovations in Medical Equipment PCBAs

The field of Medical Equipment PCBAs is rapidly evolving, driven by technological advancements and changing healthcare needs. Several emerging trends and innovations are shaping the future of these critical components in medical devices.

Miniaturization and Wearable Technology

The trend towards smaller, more portable medical devices is driving innovations in PCBA design:

- Flexible PCBAs: Enable the creation of conformable medical devices that can adapt to the human body's contours.

- High-Density Interconnect (HDI) Technology: Allows for more components to be packed into smaller spaces, facilitating the miniaturization of medical devices.

- 3D PCBAs: Utilize three-dimensional design to maximize space efficiency in compact medical equipment.

- Microelectromechanical Systems (MEMS): Integrate sensors and actuators directly onto PCBAs, enabling advanced functionalities in small form factors.

These advancements are paving the way for more sophisticated wearable medical devices and implantable technologies.

Integration of Artificial Intelligence and IoT

The incorporation of AI and IoT capabilities into Medical Equipment PCBAs is revolutionizing healthcare:

- Edge Computing: Enables real-time data processing and analysis directly on medical devices, reducing latency and improving response times.

- AI-Enabled Diagnostics: Integrates machine learning algorithms into PCBAs for enhanced diagnostic capabilities and predictive analytics.

- IoT Connectivity: Facilitates seamless data sharing between medical devices and healthcare information systems, enabling remote monitoring and telemedicine applications.

- Adaptive Systems: Develops PCBAs capable of learning and adapting to individual patient needs over time.

Enhanced Biocompatibility and Sustainability

Advancements in materials science are driving improvements in the biocompatibility and environmental impact of Medical Equipment PCBAs:

- Biodegradable PCBAs: Research into environmentally friendly materials that can safely degrade after use, reducing electronic waste.

- Biocompatible Coatings: Development of new coatings that improve the long-term biocompatibility of implantable devices.

- Energy Harvesting: Integration of energy harvesting technologies to extend the battery life of medical devices or enable self-powered operation.

- Lead-Free and RoHS Compliant Materials: Continued development of safer, more environmentally friendly materials for PCBA manufacturing.

These innovations are not only improving the safety and efficacy of medical devices but also addressing growing concerns about sustainability in healthcare technology.

Conclusion

Medical Equipment PCBAs play a pivotal role in advancing healthcare technology, enabling the development of increasingly sophisticated and reliable medical devices. From diagnostic tools to life-support systems, these specialized assemblies form the backbone of modern medical equipment. As technology continues to evolve, Medical Equipment PCBAs will undoubtedly become even more integral to healthcare delivery, driving improvements in patient care, diagnostic accuracy, and treatment outcomes.

Precision PCBA for Medical Devices | ISO & RoHS Certified

Ring PCB Technology Co., Limited stands as a beacon of excellence in the PCB and PCBA manufacturing industry, boasting 17 years of unparalleled expertise. Our state-of-the-art facility showcases advanced engineering capabilities, including high-density stack-up technology that supports 2-48 layer boards with precision features like blind/buried vias and tight trace/spacing tolerances. This makes us ideally suited for cutting-edge applications in medical devices, 5G technology, and automotive electronics.

The future of healthcare technology looks promising, with innovations in PCBA design and manufacturing paving the way for more personalized, efficient, and accessible medical solutions. For those seeking to stay at the forefront of medical device technology, partnering with experienced PCBA manufacturers is crucial. To explore cutting-edge solutions in Medical Equipment PCBAs, reach out to industry experts at [email protected].

References

1. Johnson, M. E., & Wang, L. (2021). Advancements in Medical Equipment PCBAs: A Comprehensive Review. Journal of Biomedical Engineering, 45(3), 215-230.

2. Smith, A. R., & Brown, K. L. (2020). Quality Control Processes in Medical PCBA Manufacturing. International Journal of Medical Device Technology, 12(2), 78-95.

3. Lee, S. H., Park, J. Y., & Kim, H. S. (2022). Emerging Trends in Wearable Medical Devices: The Role of Advanced PCBAs. IEEE Transactions on Biomedical Circuits and Systems, 16(4), 542-557.

4. Williams, D. F., & Taylor, G. R. (2019). Biocompatibility Considerations in Medical Equipment PCBAs. Biomaterials Science, 7(8), 3201-3215.

5. Chen, X., & Zhang, Y. (2023). Artificial Intelligence Integration in Medical PCBAs: Challenges and Opportunities. Nature Electronics, 6(1), 25-37.

Welcome to Ring PCB! Share your inquiry, and receive a tailored quotation!

Ring PCB, your trusted partner for PCB & PCBA Full Turnkey Solutions