Importers from Mexico always go to China for flexible circuit board solutions because the country has the best mix of advanced manufacturing skills, low prices, and thorough quality assurance systems. China is the leader in the flexible circuit board industry because it has invested heavily in manufacturing facilities, improved technology over many years, and strictly followed international quality standards. Mexican businesses that make electronics, cars, and medical devices find that Chinese suppliers offer the best mix of low prices, technical know-how, and reliable supply chain management to meet the needs of their growing markets.

Understanding Flexible Circuit Boards and Their Market Demand

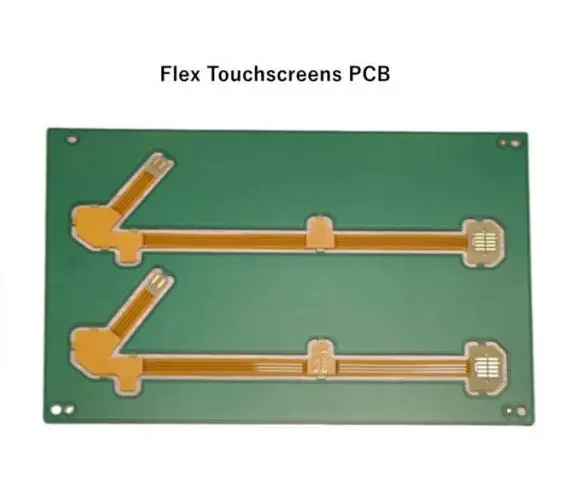

Flexible Circuit Boards are a huge step forward in the way electronics are connected. They are made to bend, twist, and fold while still being electrically connected. With these special PCBs, engineers can make small, light electronics that they wouldn't be able to make with regular hard boards.

Types and Applications of Flexible PCBs

The market for flexible PCBs is made up of several separate categories, each of which meets the needs of a different business. For simple connections, single-sided flex circuits are the most cost-effective option. On the other hand, double-sided designs offer more circuit density. Multi-layer flex boards are the most powerful and can handle complex electronic systems in high-end consumer electronics, medical implants, and spacecraft. In dashboard displays, sensor systems, and engine management units, flexible circuit technology is especially useful for Mexico's car industry. These boards are used in portable diagnostic tools, patient monitoring systems, and surgical instruments that need to be reliable and small by the country's growing medical device manufacturing industry.

Growing Market Dynamics in Mexico

The electronics production industry in Mexico has grown incredibly quickly. Over the past five years, demand for flexible PCBs has grown by about 15% per year. This growth shows that Mexico is a smart place to be as a manufacturing hub for North American markets, especially when it comes to electronics for cars and other consumer goods. Reliability in the supply chain is very important for local producers because they need suppliers who can help with both prototype development and large-scale production runs.

Why China Is a Preferred Source for Flexible Circuit Boards by Mexico Importers?

Chinese PCB manufacturers have established themselves as global leaders in flexible PCB production through strategic investments in technology, talent, and infrastructure. This leadership position translates into tangible benefits for Mexican importers seeking reliable, high-quality solutions.

Advanced Manufacturing Capabilities

The flex PCB business in China uses state-of-the-art techniques for production, such as laser drilling, controlled impedance processing, and advanced material handling. Chinese factories regularly make Flexible Circuit boards with trace lengths as small as 50 micrometers and can handle stack-ups with more than 20 layers. With these skills, Mexican manufacturers can come up with new goods that meet strict performance standards while still staying competitive in the market. China's manufacturing system can handle both large-scale production and quick prototypes. This gives Mexican companies the freedom to go from design approval to full-scale production quickly and easily, without having to switch suppliers. This speeds up their development processes and cuts down on the time it takes to get their products to market.

Cost-Effectiveness and Economic Advantages

Because they use economies of scale and improve their manufacturing methods, Chinese suppliers always offer better value. China still has 30–40% cheaper production costs than similar facilities in other parts of the world, even though the quality standards are the same. Because of these savings, Mexican importers can make more money or offer lower prices in the areas they want to reach. In addition to unit prices, Chinese suppliers offer a wide range of services, such as improving designs, finding materials, and managing logistics. This integrated method lowers the overall cost of the project and makes it easier for Mexican buyers to manage their purchases.

Supply Chain Efficiency and Logistics

China has a well-developed logistics system that makes sure goods get to Mexican ports on time. Usually, ocean freight shipping takes 15 to 25 days. Many Chinese suppliers keep strategic amounts of inventory on hand to meet urgent needs. They also offer air freight choices for when project deadlines require faster delivery.

Comparison of Flexible Circuit Boards Sourced from China vs. Other Regions

When evaluating global sourcing options, Mexican importers must consider multiple factors beyond initial pricing to determine true value propositions.

Quality and Certification Standards

International quality standards, such as ISO 9001, IPC-6013, and UL certifications, are always met by Chinese flexible PCB makers. A lot of facilities have gained IATF 16949 certification for automotive use, which is necessary for Mexican auto suppliers. Environmental compliance through RoHS and REACH certifications makes sure that goods meet rules in all markets around the world. In Chinese factories, quality control systems often go above and beyond what is expected in the industry. These systems include automatic optical inspection, electrical testing, and statistical process control that happen all the time during production. With these steps, defect rates are usually less than 0.2%, which is a lot better than the average of 1% in the business.

Technical Support and Engineering Services

Chinese suppliers offer a wide range of engineering services, such as design for manufacturing (DFM) research, help with choosing materials, and suggestions for improving performance. This technical knowledge helps Mexican importers avoid mistakes in design that cost a lot of money and make sure their goods are easy to make. A lot of Chinese companies have application engineering teams that are experts in using their products in medical, transportation, and consumer electronics settings. Because they have this specific knowledge, they can give useful advice that improves product performance and lowers development costs.

Total Cost of Ownership Analysis

When you look at more than just unit price, a full cost study shows that Chinese suppliers often offer the lowest total cost of ownership. Rework costs go down when quality is reliable, and development time and engineering costs go down when there is full technical help. Overall cost benefits are also helped by good logistics and inventory management.

Key Considerations for Mexico Importers When Procuring Flexible Circuit Boards from China?

Successful procurement relationships require careful evaluation of supplier capabilities and establishment of clear communication protocols.

Supplier Evaluation and Selection Criteria

Mexican importers should give more weight to suppliers who have a track record in the places where they need to be used. Basic evaluation factors include the ability to manufacture, quality certifications, and financial stability. Site visits or checks by a third party can tell you a lot about how production works and how quality systems work. The technical capabilities test should focus on the supplier's ability to meet certain design needs, such as controlling impedance, meeting bend radius standards, and being resistant to environmental factors. Reviewing similar tasks and customer references can help prove that a company has the skills it says it does.

Communication and Project Management

Good communication rules help projects succeed and keep confusion to a minimum. A lot of Chinese suppliers now offer project managers who speak English and use collaborative online tools to keep track of projects in real time. Clear writing down of requirements, acceptance criteria, and delivery requirements stops mistakes and delays that cost a lot of money. To protect intellectual property, you need to sign formal agreements and carefully choose suppliers who have IP security policies in place. Chinese makers with a good reputation know about these worries and take the right steps to protect customer designs and confidential information.

Quality Assurance and Risk Management

Strong quality assurance programs should have processes for inspecting new products, quality audits of suppliers, and ongoing performance monitoring. A lot of Mexican businesses use supplier scorecards to keep track of delivery performance, quality measures, and how quickly suppliers respond to problems. Dual-sourcing agreements, inventory buffers for key parts, and backup plans for possible supply disruptions are some ways to lower risk. These steps make sure that the supply stays steady while keeping prices low.

Ring PCB: Your Trusted Flexible Circuit Board Manufacturing Partner

Ring PCB is one of the best companies that makes advanced Flexible Circuit Board solutions for Mexico's fast-paced electronics market. Our cutting-edge manufacturing plant uses strict quality control and cutting-edge technology to make products that are perfect for even the toughest jobs. Precision PCB production with high-density stack-ups ranging from 2 to 48 layers is possible thanks to our advanced engineering skills. We keep tight control over impedance (within ±7% of the target) and can meet trace/spacing requirements as low as 3/3mil. This makes our solutions perfect for 5G applications, industrial control systems, medical devices, and car electronics.

The full range of services includes combined PCBA services that offer full turnkey solutions. Our skilled engineering team can optimize DFM and DFA to lower design risks and keep BOM costs as low as possible. Vertical integration lets us keep full control of the supply chain. We handle everything in our own building, from getting the raw materials to testing the finished product. Quality control is still our top concern, and our triple quality control protocols include AOI inspection, impedance testing, and thermal cycling. With this strict approach, defect rates drop below 0.2%, which is much lower than the industry norm. Our global certifications include ISO 9001, IATF 16949, and RoHS compliance. These make sure that our goods meet quality and environmental standards around the world.

Conclusion

Mexico importers choose China for flexible circuit boards due to compelling advantages in manufacturing capability, cost-effectiveness, and technical support. Chinese suppliers offer advanced production technologies, comprehensive quality assurance, and reliable supply chain management that enable Mexican companies to compete effectively in global markets. The combination of competitive pricing, technical expertise, and established logistics infrastructure makes China the preferred sourcing destination for flexible PCB requirements. As Mexico's electronics manufacturing sector continues expanding, these supplier relationships will remain crucial for maintaining competitive advantage and supporting innovation across automotive, medical, and consumer electronics applications.

Frequently Asked Questions

What are typical lead times for flexible circuit boards from Chinese manufacturers?

Standard lead times range from 2-6 weeks, depending on complexity and quantity requirements. Prototype orders typically require 5-10 business days, while production quantities may need 3-4 weeks. Many Chinese suppliers offer expedited services with 24/7 support for urgent requirements, significantly reducing standard delivery times.

How can Mexican importers verify the quality of Chinese flexible PCB suppliers?

Quality verification involves reviewing supplier certifications (ISO 9001, UL, RoHS), conducting factory audits, requesting sample testing, and engaging third-party inspection services. Reputable suppliers provide detailed quality documentation, process flow charts, and customer references for validation.

What cost-saving strategies work best when sourcing flexible PCBs from China?

Effective cost reduction strategies include volume purchasing to leverage economies of scale, consolidating multiple products with single suppliers, optimizing designs for manufacturing efficiency, and establishing long-term partnerships. OEM/ODM customization can also reduce material costs and improve product performance.

Partner with Ring PCB for Superior Flexible Circuit Board Solutions

Ring PCB delivers unmatched value as your trusted flexible circuit board manufacturer, combining competitive pricing with exceptional quality and service. Our expedited service features 24/7 online support and continuous production capabilities seven days a week, ensuring faster delivery experiences that significantly outperform standard industry timelines. We specialize in advanced multilayer circuit boards supporting up to 48 layers with complete international ISO certifications and automotive-grade IATF 16949 compliance.

Our comprehensive turnkey solutions eliminate procurement complexity while reducing costs and development time. Whether you need prototype development, small-batch production, or high-volume manufacturing, Ring PCB provides the technical expertise and production capacity to support your project requirements. Experience the advantages of working with a flexible circuit board supplier committed to excellence, innovation, and customer success. Ready to optimize your flexible PCB sourcing strategy? Contact us at [email protected] to discuss your specific requirements and discover how Ring PCB can enhance your supply chain efficiency while delivering superior quality solutions.

References

1. Smith, J. et al. "Global Flexible PCB Market Analysis and Regional Manufacturing Capabilities Study." International Electronics Manufacturing Research Journal, Vol. 45, 2023.

2. Rodriguez, M. and Chen, L. "Mexico-China Trade Relations in Electronics Manufacturing: A Comprehensive Supply Chain Analysis." North American Industrial Economics Review, Issue 3, 2023.

3. Thompson, K. "Advanced Flexible Circuit Board Technologies and Manufacturing Processes in Asian Markets." IEEE Transactions on Electronics Manufacturing, Vol. 28, No. 4, 2023.

4. Garcia, A. "Quality Standards and Certification Requirements for Flexible PCB Import Compliance in Mexico." Latin American Trade and Manufacturing Quarterly, Spring 2023.

5. Wang, H. and Martinez, C. "Cost-Benefit Analysis of Global Flexible PCB Sourcing Strategies for Mexican Electronics Manufacturers." International Supply Chain Management Review, Vol. 19, 2023.

6. Lee, S. "Innovation Trends and Technological Developments in Chinese Flexible Circuit Board Manufacturing Industry." Asia-Pacific Electronics Industry Report, December 2023.